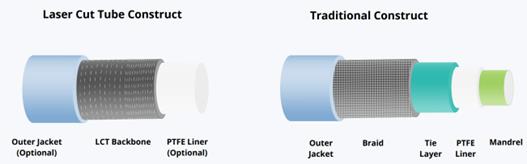

Figure 1: Braid Based vs Lasercut Hypotube Based Catheter Construction

S no |

Mechanical Property |

Clinical Relevance |

Design objective |

Design option |

1 |

Pushability: ability to exert longitudinal force from the proximal end to distal end of the shaft |

Allows the physician to easily push the device to the target treatment site |

Maximize the pushability of the catheter |

Maximize

|

2 |

Torque transmission: ability to transmit proximal end input torque to distal end output torque |

Allows for rotation of the implant in the intended orientation with respect to the patient anatomy |

Maximize the torque transmission with minimal inter-shaft frictional loss |

Maximize

|

3 |

Trackability: ability to flex with application of minimal bending force |

Allows the catheter to bend and conform to the patient’s anatomy without causing traumatic vascular damage |

Maximize the bendability |

Minimize

|

4 |

Kink Radius- ability to bend around corners without distortion of cross-sectional shape of the catheter |

Allows for easier delivery of implants and ancillary devices like guidewires through the catheter lumen to the target treatment site |

Retain the cross-sectional shape of the catheter with minimal shape distortion |

Maximize

Minimize

|

Table 1 : Catheter Mechanical Properties, their clinical relevance and design options to achieve them

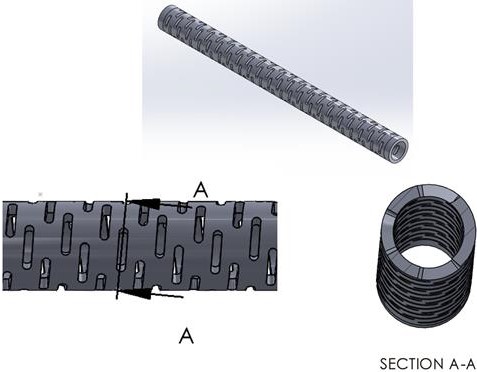

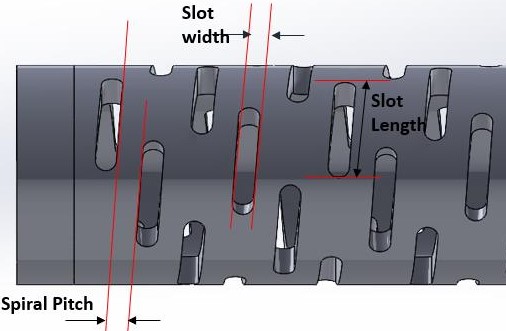

Slot Length |

Uncut length between slots |

Spiral Pitch |

Slot Width |

Number of slots per rotation |

Table 2 : Critical Parameters-Interrupted Spiral Pattern

S No |

Design Parameters |

Values |

1 |

LCH Outer Diameter (OD) |

0.134 inches |

2 |

LCH Inner Diameter (ID) |

0.100 inches |

3 |

LCH Length |

1.5 inches |

4 |

Number of slots per spiral rotation |

3 count |

5 |

Total Number of Slots |

180 count |

Table 3 : Parameter Constants used for the LCH Model Design

S No |

LCH Parameter |

Low (inches) |

High (inches) |

1 |

Spiral Pitch |

0.020 |

0.035 |

2 |

Slot Width |

0.003 |

0.007 |

3 |

Arc Cut Length |

0.056 |

0.084 |

Table 4 : LCH Critical Parameter Ranges for Design Optimization

Parameter |

Value |

Material Model |

Linear Elastic-Plastic |

Young’s Modulus(psi) |

2.9E7 |

Poisson’s Ratio |

0.29 |

Plastic Behavior (Stress, Strain) |

(137000,0.00) |

Ultimate Strain (%) |

20 |

Table 5 : FEA Material Model Parameters

Input Variables |

Input Variables Level |

||||

Low |

Center |

High |

Axial(-α) |

Axial(+α) |

|

Spiral Pitch (P) |

0.020 |

0.0275 |

0.035 |

0.0149 |

0.0401 |

Slot Width (SW) |

0.003 |

0.005 |

0.007 |

0.0016 |

0.0084 |

Slot Arc Length (SL) |

0.056 |

0.070 |

0.084 |

0.0465 |

0.0935 |

Table 6 : Input Levels for Central Composite Design (CCD)

Run Order |

Blocks |

Input Variables |

Response Variables |

||||

Slot Width |

Slot Arc Length |

Spiral Pitch |

Tensile Stiffness (lbf/in) |

Torsional Stiffness |

Bending Stiffness |

||

1 |

1 |

0.0030 |

0.0560 |

0.0200 |

149.60 |

10.93 |

17.00 |

2 |

1 |

0.0070 |

0.0560 |

0.0200 |

79.40 |

7.20 |

8.42 |

3 |

1 |

0.0030 |

0.0840 |

0.0200 |

31.19 |

5.75 |

3.59 |

4 |

1 |

0.0070 |

0.0840 |

0.0200 |

7.01 |

2.83 |

0.85 |

5 |

1 |

0.0030 |

0.0560 |

0.0350 |

256.20 |

9.88 |

25.17 |

6 |

1 |

0.0070 |

0.0560 |

0.0350 |

185.80 |

6.33 |

14.25 |

7 |

1 |

0.0030 |

0.0840 |

0.0350 |

101.40 |

3.58 |

9.65 |

8 |

1 |

0.0070 |

0.0840 |

0.0350 |

34.68 |

0.80 |

3.83 |

9 |

1 |

0.0016 |

0.0700 |

0.0275 |

93.83 |

10.30 |

10.20 |

10 |

1 |

0.0084 |

0.0700 |

0.0275 |

30.76 |

5.47 |

1.84 |

11 |

1 |

0.0050 |

0.0465 |

0.0275 |

136.40 |

12.55 |

15.94 |

12 |

1 |

0.0050 |

0.0935 |

0.0275 |

24.31 |

4.02 |

1.82 |

13 |

1 |

0.0050 |

0.0700 |

0.0149 |

7.12 |

2.99 |

0.29 |

14 |

1 |

0.0050 |

0.0700 |

0.0401 |

95.42 |

3.20 |

10.69 |

15 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

16 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

17 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

18 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

19 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

20 |

1 |

0.0050 |

0.0700 |

0.0275 |

47.10 |

7.60 |

5.04 |

Table 7 : CCD Matrix and FEA Simulation Data for Responses

|

Response Variables |

||

|

Tensile Stiffness (lbf/in) |

Torsional Stiffness (lbf-in/rad) |

Bending Stiffness |

Target Range |

5-10 |

8-13 |

5-10 |

Table 8 :Response Variables-Target Ranges

Regression Coefficient |

Tensile Stiffness (y1) |

Bending Stiffness(y2) |

Torsion Stiffness(y3) |

|||

Regression coefficient |

Associated p-value for the term |

Regression coefficient |

Associated p-value for the term |

Regression coefficient |

Associated p-value for the term |

|

η0 |

724 |

0.000 |

97.9 |

0.000 |

4.89 |

0.000 |

η1 |

-52606 |

0.012 |

-6403 |

0.000 |

-1364 |

0.000 |

η2 |

-15345 |

0.000 |

-1941 |

0.000 |

-255 |

0.000 |

η3 |

6174 |

0.002 |

168 |

0.001 |

1768 |

0.000 |

η21 |

3451025 |

0.110a |

268541 |

0.100a |

2293 |

0.951a |

η22 |

103007 |

0.028 |

10641 |

0.006 |

770 |

0.324a |

η23 |

176097 |

0.237a |

15763 |

0.166a |

-29947 |

0.000 |

η12 |

221879 |

0.570a |

48858 |

0.117a |

7084 |

0.334a |

η13 |

-356175 |

0.624a |

-45234 |

0.414a |

2623 |

0.844a |

η23 |

-137049 |

0.203a |

-5898 |

0.455a |

-2723 |

0.174a |

R2 (Model) |

0.885 |

- |

0.934 |

- |

0.983 |

- |

R2(adj) (Model) |

0.782 |

- |

0.874 |

- |

0.967 |

- |

3Lack of Fit (F-value) for Model |

8.57 |

- |

15.69 |

- |

62.63 |

- |

Lack of Fit (P-value) for Model |

0.001 |

- |

0.000 |

- |

0.000 |

- |

|

||||||

ηi: the estimated regression coefficient for the main linear effects. ηii: the estimated regression coefficient for the quadratic effects. ηij: the

estimated regression coefficient for the interaction effects. 1: Slot width; 2: slot arc length; 3: spiral pitch. a- statistically insignificant

(p>0.05)

Table 9 : Regression coefficients, R2, adjusted R2, probability values and lack of fit for the initial regression models

|

Tensile Stiffness |

Bending Stiffness |

Torsional Stiffness |

Minitab Model Prediction |

99.99 |

8.99 |

8.5 |

FEA Test Result |

79.9 |

5.81 |

8.61 |

% Error |

20% |

35% |

-1% |

Table 10 : % Error Between Minitab Model and FEA Simulation

Figure 1: Braid Based vs Lasercut Hypotube Based Catheter Construction

Figure 2: Common Lasercut Patterns

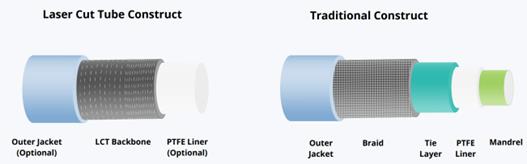

Figure 3: CAD Model- Interrupted Spiral Lasercut Pattern

Figure 4: Critical Parameters Definition- Interrupted Spiral Lasercut Pattern

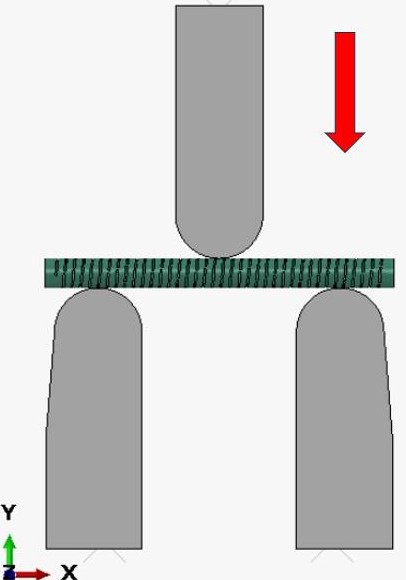

Figure 5: Test Setup-3pt Bend Test

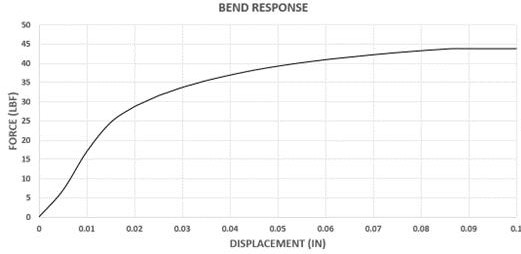

Figure 6: Force vs Displacement Curve- 3Pt Bend Test

Figure 7: Test Setup-Torsion Test

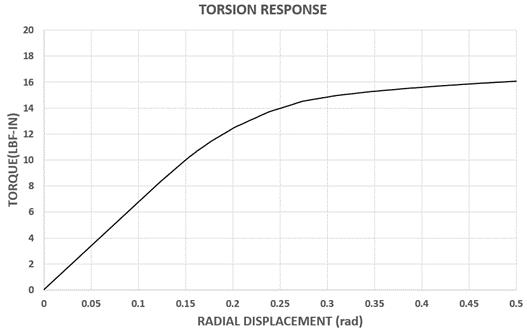

Figure 8: Torque vs Radial Displacement Curve- Torsion Test

Figure 9:Test Setup-Tensile Test

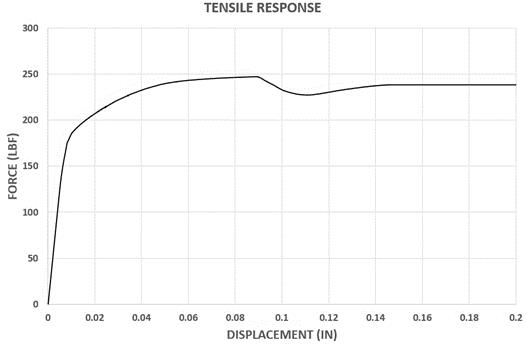

Figure 10: Force vs Displacement Curve- Tensile Test

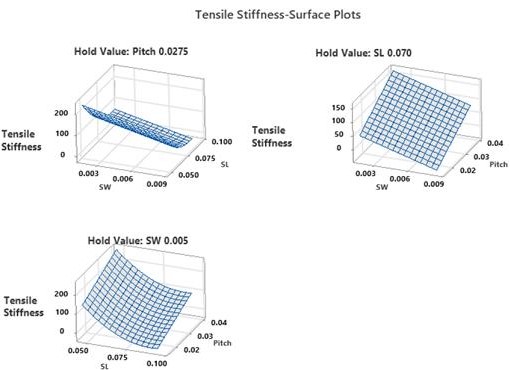

Figure 11: 3D Surface Plots- Tensile Stiffness

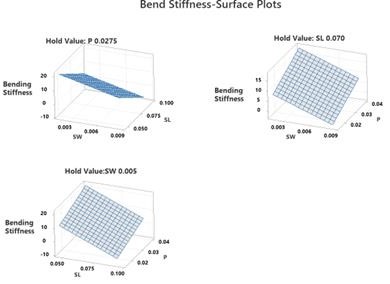

Figure 12: 3D Surface Plots- Bend Stiffness

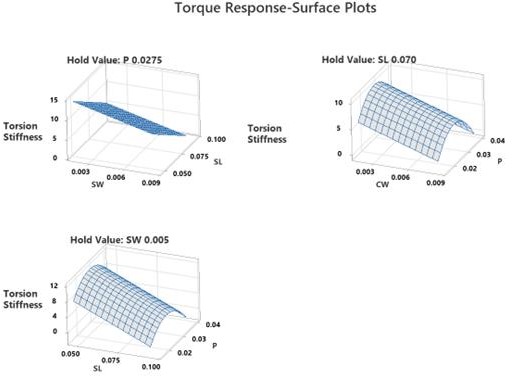

Figure 13: 3D Surface Plots- Torsional Stiffness

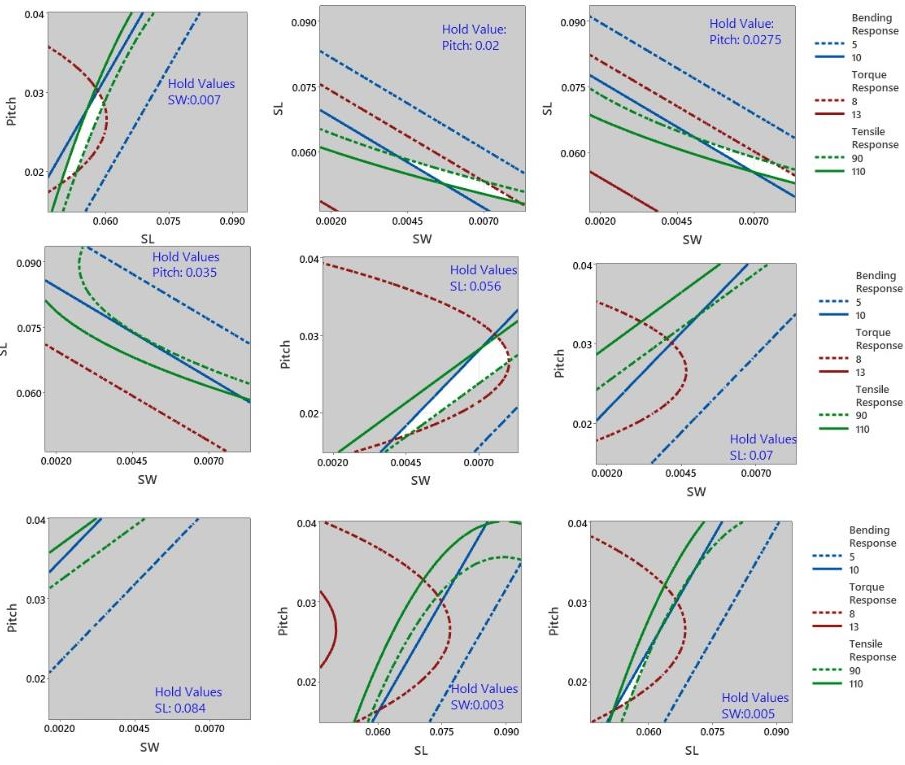

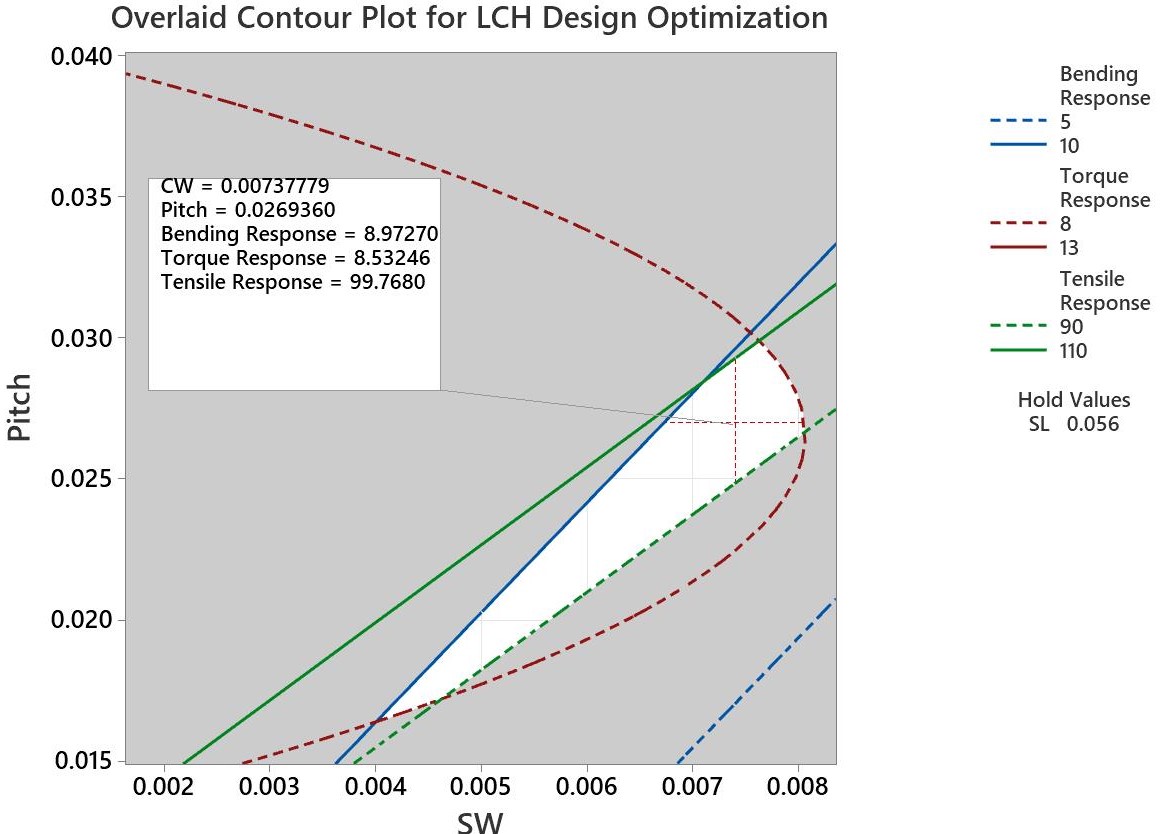

Figure 14: Overlaid Contour Plot Matrix

Figure 15: Overlaid Contour Plot- Pitch vs SW

Tables at a glance

Figures at a glance