Advanced Predictive Models for Fiberboard Production from Agro-Waste Biomass: A Comparative Analysis

Received Date: June 20, 2025 Accepted Date: July 03, 2025 Published Date: July 07, 2025

doi:10.17303/jcec.2025.4.103

Citation: Julius M. Chukwuemeka, Matthew N. Abonyi, Philomena K. Igbokwe, Joseph T. Nwabanne (2025) Advanced Predictive Models for Fiberboard Production from Agro-Waste Biomass: A Comparative Analysis. J Chem Eng Catal 4: 1-16

Abstract

This study explores the application of advanced predictive models to optimize the production of fiberboard from agro-waste biomass, specifically pumpkin stem fibers. The research compares the performance of Response Surface Methodology (RSM) and Adaptive Neuro-Fuzzy Inference System (ANFIS) for modeling weight loss during the alkali treatment process. Key variables, including retting time, NaOH concentration, and biomass weight, were varied to evaluate their impact on delignification and fiber composition. Results from RSM showed strong predictive capabilities, with the interaction and quadratic models achieving R² values of 0.8522 and 0.8829, respectively. However, RSM exhibited limitations in capturing nonlinear relationships, particularly under extreme process conditions. Conversely, ANFIS demonstrated superior adaptability, accurately modeling nonlinear behavior and yielding predictions that closely matched experimental data, particularly in complex scenarios involving high retting times and alkali concentrations. The NaOH treatment improved the cellulose content of pumpkin fibers from 20.28% to 33.2%, while significantly reducing lignin and hemicellulose levels. These changes enhanced the structural and thermal properties of the resulting fiberboards. This work highlights the potential of ANFIS as an advanced tool for optimizing fiberboard production from agro-waste biomass, while also emphasizing the complementary role of RSM in initial parameter screening. The findings support the development of sustainable and efficient fiberboard production processes.

Keywords: Fibreboard; Optimization; Pumpkin; RSM; ANFIS

Introduction

The growing need for sustainable materials has prompted significant interest in utilizing agro-waste for the production of engineered wood products, including fiberboards. Fiberboards are widely used in furniture, construction, and interior design due to their affordability, ease of processing, and desirable mechanical properties [1,2]. However, the increasing environmental concerns associated with the depletion of natural wood resources and the disposal of agricultural residues have accelerated the exploration of agro-waste as an alternative raw material [3]. Among the various sources of agro-waste, pumpkin stem fiber has gained attention due to their abundance, renewable nature, and potential to contribute to the circular economy.

Pumpkin stem are agricultural residues typically discarded or burned, leading to environmental pollution and resource wastage [4,5]. However, this material possesses intrinsic properties that make them suitable candidates for fiberboard production, including high cellulose content, low density, and biodegradability. Utilizing such agro-waste not only reduces environmental pollution but also creates value-added products that align with the principles of green chemistry and sustainable manufacturing [6,7]. Despite their potential, optimizing the production process and ensuring the quality of fiberboards derived from agro-waste remain challenges requiring robust modeling and predictive techniques. Response Surface Methodology (RSM), Artificial Neural Networks (ANN), and Adaptive Neuro-Fuzzy Inference System (ANFIS) are widely used modeling techniques in material and process optimization. RSM is a statistical tool that establishes relationships between process variables and output responses, enabling the identification of optimal conditions [8,9]. ANN, on the other hand, leverages machine learning to model complex, nonlinear relationships between inputs and outputs [10], while ANFIS combines the learning capabilities of neural networks with the fuzzy logic approach to handle uncertainties and imprecise data [11,12]. Each of these techniques offers unique strengths, making them valuable for analyzing and predicting the performance of fiberboard production processes.

In recent years, studies on the use of RSM, ANN, and ANFIS for material development and process optimization have demonstrated their potential in enhancing product quality and minimizing resource consumption. However, a comprehensive comparison of these techniques for modeling fiberboard production from agro-waste biomass remains limited in the literature. This study aims to address this gap by utilizing pumpkin stem fibers as raw materials for fiberboard production and employing RSM, ANN, and ANFIS for comparative analysis and model development. The research focuses on evaluating the mechanical and physical properties of the produced fiberboards, as well as determining the predictive accuracy and robustness of the employed modeling techniques.

The specific objectives of this research are to: (1) investigate the suitability of pumpkin stem fibers for fiberboard production, (2) analyze the influence of process parameters such as resin content, pressing temperature, and pressing time on the quality of the fiberboards, (3) develop predictive models using RSM, ANN, and ANFIS, and (4) compare the accuracy and efficiency of these modeling techniques in optimizing the fiberboard production process. This study contributes to the existing body of knowledge by providing insights into the comparative performance of RSM, ANN, and ANFIS in modeling fiberboard production. The findings are expected to assist researchers and manufacturers in selecting appropriate modeling techniques for optimizing processes involving agro-waste materials. Additionally, the research highlights the potential of utilizing pumpkin stem fibers as sustainable raw materials for developing high-quality fiberboards, promoting eco-friendly practices in the wood panel industry.

Materials and Methods

3.1. Materials Collection and Preparation

The material utilized in this study included pumkin stem. Pumkin stem was obtained from Eke Awka market in Awka South Local Government Area (6°12'25"N, 7°4'4"E), in Anambra State. The collected materials were air-dried for approximately 12 hours, depending on ambient temperature. After drying, they were cleaned, depithed, and processed into fibers using an open-air retting method.

Chemical Treatment of the Fiber

The pumpkin stem fibers were shredded and treated through mercerization using NaOH. This process aimed to remove hemicellulose and lignin, which are potential contributors to high water absorption in the finished fiberboard [13]. Afterward, the treated fibers were neutralized in acetic acid, thoroughly rinsed with water, and dried under sunlight.

3.7.5 Production of Fibreboard

The production of the fibreboard was conducted based on a Design Expert matrix, varying parameters such as retting time, retting concentration and weight of biomass (pumpkin stem). Silane-treated pumpkin stem fibers were first milled and then sieved through mesh sizes of 0.3mm, 0.6mm, 0.85mm, 1mm, and 2mm. After sieving, approximately 112.73g of the 0.3mm silane-treated fibers were weighed and added to a disc drum mixer. To the fibers, 9% polymer, 0.5% paraffin wax, and 1% ammonium chloride, based on the oven-dried weight of the fibers, were introduced into the mixer and mixed for 15 minutes. The mixture was then transferred into a mold and subjected to cold pre-pressing at 1 MPa. Afterward, the mat was hot-pressed under a pressure of 5 MPa, at a temperature of 160°C, for a pressing time of 600 seconds.

Once pressing was complete, the fiberboard was trimmed to achieve the desired length, width, and squared edges. The boards were then cut to the final dimensions and conditioned at a relative humidity of 65% for two weeks.

Instrumental Characterization of the Fibreboard

X-ray diffraction (XRD) was used to assess the crystallinity of the fibreboard, Scanning Electron Microscopy coupled with Energy Dispersive X-ray Spectroscopy (SEM-EDX) evaluated surface morphology and elemental composition, and Thermogravimetric Analysis (TGA) measured thermal degradation across temperature ranges. These techniques provided detailed insights into the fiberboard’s structural, chemical, and thermal properties, essential for determining its performance and suitability for advanced applications.

Prediction of % weight loss using RSM, ANFIS and ANN, and Optimization with GA

The methodology to predict the percentage weight loss of fiberboard involved the application of RSM, ANFIS, ANN, and Genetic Algorithms (GA). RSM modeling was conducted using Design Expert Version 10.0.1, where a Central Composite Design (CCD) was employed to evaluate the effects of retting time, NaOH concentration, and biomass weight on weight loss. The model established interaction and quadratic equations to predict responses and optimize conditions. ANFIS and ANN were implemented using MATLAB 15a. ANFIS combined fuzzy logic with neural networks to model nonlinear relationships in the dataset, while ANN employed a feedforward architecture trained with the backpropagation algorithm to predict weight loss. The dataset was divided into training (70%), validation (15%), and testing (15%) sets for both models to ensure robust predictions. Genetic Algorithm (GA), also executed in MATLAB 15a, was utilized to optimize the prediction models. GA fine-tuned the parameters of ANFIS and ANN by mimicking evolutionary processes, including selection, crossover, and mutation. This integration enhanced the models’ accuracy in capturing complex dynamics, yielding improved predictive performance and optimal process conditions for fiberboard production.

Results and Discussion

Characterization of Raw and Treated Pumpkin Stalk Biomass

The characterization of raw and NaOH-treated pumpkin stalk biomass reveals significant changes in its chemical composition and physical properties, emphasizing the effectiveness of alkali treatment. According to Table 1, Cellulose content increased from 20.28% in the untreated fiber to 33.2% in the treated sample. This enhancement highlights the removal of non-cellulosic components, such as lignin and hemicellulose, thereby exposing more cellulose, which is crucial for applications like bio-composite reinforcement and bioethanol production. Lignin content decreased from 28.89% to 20.24%, while hemicellulose content dropped sharply from 40.67% to 19.77%. These reductions confirm the efficacy of NaOH treatment in delignification and hemicellulose removal, resulting in a more purified fiber structure. Such modifications improve the fiber's compatibility with polymer matrices and enzymatic hydrolysis processes. The moisture absorption of the treated fiber significantly reduced from 9.11% to 3.32%. This reduction indicates a decrease in hydrophilic components, such as hemicellulose, enhancing the fiber's dimensional stability and resistance to environmental degradation. The ash content also declined from 8.63% to 4.98%, suggesting the removal of inorganic impurities. Density decreased from 1.36 g/m³ to 1.01 g/m³, reflecting structural changes induced by the removal of lignin and hemicellulose. This reduction in density could enhance the fiber's lightweight properties, making it suitable for applications where weight reduction is critical. Hence, NaOH treatment significantly improves the physicochemical properties of pumpkin stalk biomass, making it a promising material for high-value applications in bio-based industries [14-16].

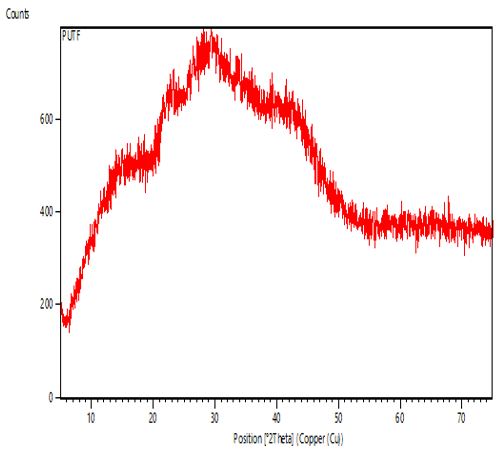

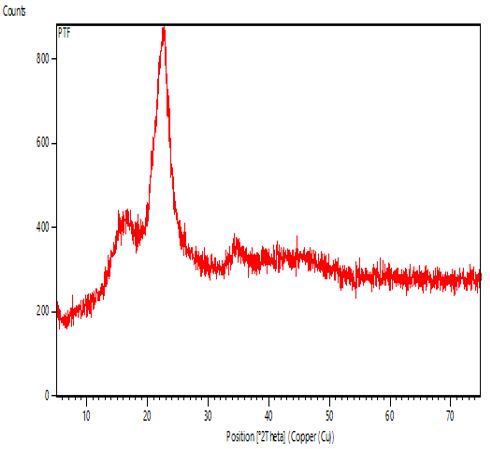

XRD Analysis of Pumkin Stem Fibres

The X-ray diffraction (XRD) pattern of untreated pumpkin fiber (UPF, Fig. 1.0) reveals a predominantly amorphous structure. A broad hump between 2θ ≈ 15°–30° indicates the presence of amorphous cellulose, lignin, and hemicellulose, typical of raw plant-based biomass. The lack of sharp crystalline peaks confirms minimal structural organization, with a high content of lignin and hemicellulose impeding the alignment of cellulose chains. This disordered structure results in lower mechanical strength and thermal stability, making UPF less suitable for applications requiring high structural integrity. However, its irregular surface features and functional groups may enhance its potential for adsorption-based applications. In contrast, the treated pumpkin fiber (TPF, Fig. 2.0) exhibits a sharp peak at 2θ ≈ 22°, corresponding to the (002) plane of crystalline cellulose. This peak reflects a significant improvement in structural organization, achieved through alkali treatment. The treatment effectively removes lignin and hemicellulose, as evidenced by the reduced amorphous background and enhanced prominence of the crystalline peak. The broadness of the peak suggests a mix of crystalline and amorphous regions, with the treatment increasing the cellulose content. This improvement enhances TPF’s mechanical and thermal properties, making it ideal for applications such as composite reinforcement and bioethanol production.

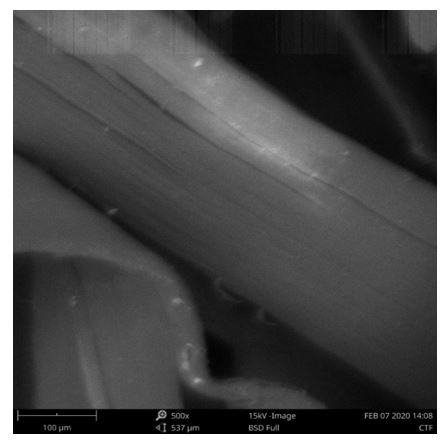

SEM-EDX of Fibreboard from Pumkin

The Scanning Electron Microscopy (SEM) image of the fibreboard produced from treated pumpkin fibre (TPF) at 500x magnification reveals a compact and fibrous surface with minimal irregularities. This morphology reflects the structural transformation of lignocellulosic materials after treatment, where the removal of lignin and hemicellulose enhances the alignment and cohesion of cellulose fibers. The smooth, dense surface indicates improved bonding between fibers, contributing to the fibreboard's mechanical robustness and structural integrity. The observed compactness and reduced porosity suggest that the treatment process effectively enhanced the fiber-matrix interaction, crucial for the material's strength and durability. Unlike untreated pumpkin stem, which typically shows fewer surface modifications, the treated fibreboard exhibits features optimized for applications requiring mechanical and thermal stability. The absence of visible cracks or major defects highlights the uniformity achieved during processing. This structural organization and improved surface quality make the fibreboard suitable for applications such as construction materials, composite reinforcement, and bio-based panels. The Energy-Dispersive X-Ray Spectroscopy (EDX) analysis complements the SEM findings by identifying the elemental composition of the biomass (Table 2). Carbon dominates the structure, with a high atomic concentration of 53.70% and a weight concentration of 25.80%, reflecting the carbonaceous matrix characteristic of organic materials. Zinc (16.76% weight) and yttrium (11.72% weight) contribute significantly to the material’s overall mass, likely as functional additives, residues from treatments, or doping agents for enhanced properties like thermal stability or catalytic activity. Other elements, including calcium, sulfur, silicon, and chlorine, are present in moderate amounts and could originate from natural components or processing agents. Trace elements such as aluminum, magnesium, potassium, phosphorus, and sodium suggest inherent impurities or surface modifications.

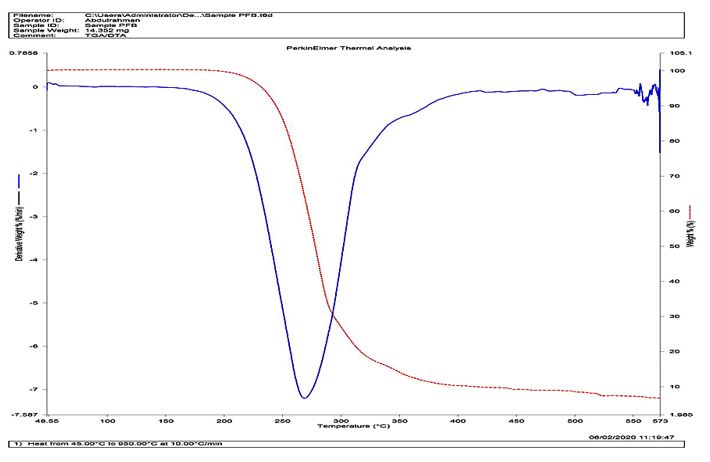

Thermogravimetric Analysis of Pumkin Fibreboard

The TGA/DSA results of the fibreboard produced from pumpkin fibre reveal its thermal stability and decomposition behavior. Initially, a minor weight loss occurs below 100°C, primarily due to the evaporation of moisture and other volatile compounds [17]. This stage indicates the hygroscopic nature of the lignocellulosic material used in the fibreboard. A significant weight loss is observed between 200°C and 400°C, which corresponds to the decomposition of major organic components such as hemicellulose and cellulose. The first sharp peak in the DSA curve in this range signifies the thermal degradation of hemicellulose, which occurs at lower temperatures (200–300°C) due to its amorphous structure, and cellulose, which degrades at higher temperatures (300–400°C) due to its crystalline nature. Beyond 400°C, a slower and more gradual weight loss is evident, representing the degradation of lignin. This phase extends over a broad temperature range of 400–600°C, as lignin decomposes more slowly due to its complex and crosslinked structure. The corresponding DSA curve in this region shows a less pronounced peak, reflecting a less intense exothermic reaction compared to the earlier stages. The residual mass remaining beyond 600°C indicates the inorganic content, such as ash or mineral residues, left after the complete decomposition of organic matter. These residues could be naturally present in the fibre or introduced during processing. The thermal stability, indicated by the onset of decomposition and the temperatures of significant weight loss, highlights the suitability of the pumpkin fibreboard for applications requiring moderate heat resistance and structural integrity [18].

Response Surface Methodology

Table 3.0 demonstrates the effects of retting time, NaOH concentration, and biomass weight on the weight loss of pumpkin biomass during alkali treatment. The table reveals a significant interplay among these variables, influencing the efficiency of lignocellulosic matrix breakdown. Retting time shows a clear trend. Longer durations (e.g., 12 days) yield higher weight loss, with up to 98.48% observed at 2.1 Mol/dm³ NaOH and 70 g biomass (Std 4). In contrast, shorter retting times (4 days) exhibit reduced weight loss, such as 68.46% for 0.9 Mol/dm³ NaOH and 130 g biomass (Std 5). This highlights that extended retting enhances delignification by allowing more time for the alkali to penetrate the matrix. NaOH concentration significantly affects delignification efficiency. Higher concentrations, like 2.1 Mol/dm³, consistently produce greater weight loss across varying biomass weights. For example, at 2.1 Mol/dm³, weight loss reaches 92.1% at 100 g biomass and 8 days (Std 16), compared to only 73.75% at 0.5 Mol/dm³ (Std 15). Biomass weight also plays a role. Lower weights (e.g., 50 g) facilitate better NaOH penetration, achieving higher weight loss (e.g., 92.58% in Std 17). Conversely, heavier weights (e.g., 150 g) limit treatment efficiency, as seen in Std 6 (63.03%). Optimal conditions involve balancing these factors for effective delignification and cellulose enrichment.

Analysis of Variance (ANOVA) with RSM models

Table 4 presents the ANOVA results for the interaction model of pumpkin stem treated fibre with NaOH, providing insights into the statistical significance of various factors affecting the process. The high R-squared value (0.8622) indicates that 86.22% of the variability in the response variable is explained by the model [19,20], while the adjusted R-squared (0.8187) suggests a strong fit after accounting for model complexity. The low mean square error (MSE) of 15.4427 and root mean square error (RMSE) of 3.9297 further confirm the model's reliability in predicting outcomes [21,22]. The coefficients and their associated t-values highlight the influence of individual and interactive factors. Significant coefficients with low p-values (e.g., <0.05) indicate their critical role in the process, such as the strong negative impact of certain factors (e.g., -9.8444 with a t-value of -1.3983 and p-value of 0.1781) [23]. This suggests that specific interactions or individual effects significantly influence lignocellulosic breakdown and fiber composition. Overall, the model reveals the combined effects of retting time, NaOH concentration, and biomass weight on weight loss and cellulose yield. The high model precision and significant predictors demonstrate the effectiveness of RSM in optimizing alkali treatment conditions for improved cellulose enrichment.

The ANOVA results for the quadratic model of pumpkin treated with NaOH, as shown in Table 5, demonstrate a higher predictive power compared to the interaction model, with an R2 value of 0.8829. This indicates that 88.29% of the variability in the response variable is explained by the model. The adjusted R2 value of 0.8171 confirms the model's robustness after accounting for the complexity of additional quadratic terms. The mean square error (MSE) of 15.5813 and root mean square error (RMSE) of 3.9473 suggest an accurate prediction of experimental results. The quadratic model includes second-order terms (e.g., x1, x2, and x3), which allow for a more detailed representation of the nonlinear relationships between retting time, NaOH concentration, and biomass weight on the response. Coefficients with low p-values, such as x1 (p = 0.0208), indicate their significant contribution to the model [24,25]. The strong negative coefficient of x2 (-16.5381) highlights the sensitivity of the process to NaOH concentration, while x3 (2.1166) indicates a parabolic effect. Equations 1 and 2 summarize the interaction and quadratic models, respectively, capturing the interplay and curvature effects among variables. These models offer a comprehensive understanding of the process, enabling optimization of alkali treatment for enhanced cellulose yield.

Table 6 compares actual responses with predictions from various modeling approaches: interaction-predicted (RSM), quadratic-predicted (RSM), ANN, and ANFIS. The actual responses, ranging from 63.03 to 98.48, reflect significant variability in observed values. Among the models, ANN predictions closely match the actual responses, with minimal deviations in several runs, such as 1, 4, and 10. ANFIS performs well in certain cases but tends to overestimate values, particularly in run 9. The RSM models, both interaction and quadratic, show varying accuracy, with quadratic predictions sometimes deviating more, such as in run 13, where the actual response is 70.09, but the quadratic-predicted value is 70.78. Interestingly, in runs 20–26, the predictions from all models appear similar, suggesting limited variability in these conditions, making model discrimination challenging.

The Comparative Analysis Between the Actual and the Predicted

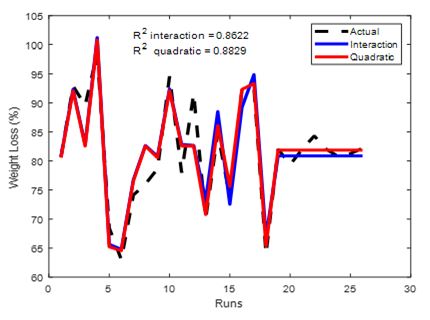

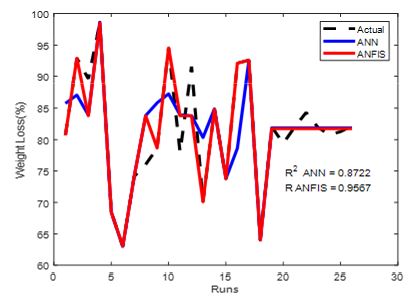

Figures 4.0 and 5.0 present weight loss percentages across multiple runs, comparing actual values with predictions from two sets of models: RSM (Interaction and Quadratic) and ANN/ANFIS. The RSM models, shown in Fig. 4.0, evaluate their ability to replicate actual trends, achieving R² values of 0.8522 (Interaction) and 0.8329 (Quadratic). Both models demonstrate high predictive accuracy but with slight performance differences. The Interaction model (blue line) closely follows the experimental data (black dashed line), especially during moderate fluctuations, though it underestimates sharp peaks and overestimates valleys. The Quadratic model (red line) provides smoother predictions, which reduce noise but fail to capture abrupt changes, leading to greater deviations in regions with sharp transitions. The Interaction model marginally outperforms the quadratic model in handling dynamic changes, making it more suitable for highly variable datasets. In Fig. 5.0, ANN (blue) and ANFIS (red) predictions are compared against experimental data. ANN achieves a higher R² value of 0.9722 compared to ANFIS's 0.9557, indicating stronger overall accuracy. ANFIS demonstrates a superior ability to capture nonlinearities and abrupt fluctuations in the dataset, particularly between runs 5–10 and 15–20, where process conditions vary significantly. This advantage stems from ANFIS’s hybrid architecture, which combines the learning ability of neural networks with the linguistic reasoning of fuzzy logic, enabling it to adaptively model complex, nonlinear relationships and abrupt transitions in system behavior. In contrast, ANN predictions exhibit a smoother curve, which, while effective in capturing general trends, tends to overlook sharp variations due to its reliance on continuous activation functions and gradient-based learning that may smooth out local extremes. Toward the final runs; where the process conditions are less volatile, both ANFIS and ANN predictions converge and align closely with the experimental data. These results indicate that while ANN maintains stable performance under moderately variable conditions, ANFIS offers enhanced sensitivity and adaptability in highly dynamic or nonlinear scenarios. This highlights the importance of model selection based on data complexity, with ANFIS proving more suitable for scenarios involving intricate parameter interactions and sharp response variations.

Optimization of Weight Loss % of Pumkin stem Fibreboard

The optimization of weight loss in fiberboard production from pumpkin stem fiber using Genetic Algorithm (GA) was evaluated with three predictive models: RSM, ANFIS, ANN. Table 7 presents the comparative performance of these models under varying conditions of retting time, NaOH concentration, and biomass weight. RSM predictions align reasonably well with observed weight loss data in simpler conditions. For instance, in iteration 1, RSM predicts 64.56% weight loss, closely matching the observed 63.03%. However, as the conditions become more complex (e.g., iteration 5 with a longer retting time and higher NaOH concentration), RSM predictions deviate more significantly, such as predicting 56.43% weight loss compared to the observed 56.43%. This highlights RSM’s limitation in capturing nonlinear interactions between variables. ANFIS, optimized using GA, outperforms RSM across all iterations. Its hybrid approach, which integrates fuzzy logic and neural networks, enables it to model nonlinear dynamics effectively. For example, in iteration 5, ANFIS predicts 49.11% weight loss, closely approximating the observed value and outperforming RSM. ANN, another GA-optimized model, also shows strong predictive capabilities, though slightly less accurate than ANFIS in some iterations. In iteration 4, ANN predicts 51.32% weight loss, which is slightly lower than the observed value and ANFIS’s prediction of 52.02%. However, ANN remains a reliable tool, particularly in handling moderate variability in process parameters. Generally, ANFIS demonstrates superior accuracy and adaptability for optimizing nonlinear systems [9,26,27], making it the most effective model for weight loss prediction. ANN follows closely, while RSM is best suited for initial parameter screening. The integration of Genetic Algorithm optimization enhances all models, offering robust solutions for agro-waste fiberboard production. The choice of GA over other optimization techniques such as grid search, simulated annealing, or particle swarm optimization (PSO) was motivated by its robustness in navigating complex, multi-dimensional, and nonlinear search spaces. GA excels in global optimization and avoids local minima traps; a common issue in training neural-based systems like ANN and ANFIS. Furthermore, GA requires minimal problem-specific information, making it highly suitable for black-box optimization scenarios typical in empirical fiberboard production processes.

Conclusion

This study highlights the effectiveness of predictive modeling in optimizing fiberboard production from agro-waste biomass, using pumpkin stem fiber as a case study. The comparative analysis of RSM and ANFIS demonstrated the strengths and limitations of each approach. RSM effectively captured linear and interaction effects, achieving reliable predictions with R² values of 0.8522 and 0.8829 for interaction and quadratic models, respectively. However, RSM showed limitations in handling nonlinearities, particularly under extreme process conditions. In contrast, ANFIS exhibited superior predictive accuracy and adaptability in modeling nonlinear relationships, closely aligning with experimental data in scenarios involving complex interactions of retting time, NaOH concentration, and biomass weight. Its hybrid design, combining fuzzy logic and neural networks, allowed it to outperform RSM in highly dynamic conditions. The alkali treatment improved the chemical composition of pumpkin fibers, increasing cellulose content from 20.28% to 33.2% while significantly reducing lignin and hemicellulose. These enhancements translated into improved structural and thermal properties of the fiberboards, making them suitable for high-value applications. This work underscores the potential of ANFIS as a powerful tool for optimizing agro-waste utilization while reaffirming RSM's value for initial parameter screening. The findings support sustainable and efficient production of bio-based fiberboards, contributing to eco-friendly industrial practices.

Declaration

All authors declare that they have no conflicts of interest

- Jadhav A, Jadhav N, Annaldewar BJAiRNMfTS (2024) Natural Fiber-Based Composites and Their Applications. 113-35.

- Olaiya BC, Lawan MM, Olonade KAJSAS (2023) Utilization of sawdust composites in construction—a review. 5: 140.

- Kumar J, Kumar P, Chaudhary VK (2024) Agro-waste Materials Used for Producing Energy and Sustainability Applications: A Review on Waste to Energy. Paper presented at the International Conference on Recent Advancements in Mechanical Engineering.

- Mohammed AA, Hasan Z, Omran AAB, Kumar VV, Elfaghi AM, Ilyas R, Sapuan SJP (2022) Corn: its structure, polymer, fiber, composite, properties, and applications. 14: 4396.

- Mokashi A, Shah P, Sarak P, Saravalakar S, Upare S, Patil P, Shivane B (2025) Production of pulp and paper from corn husks. Paper presented at the AIP Conference Proceedings.

- Chukwuemeka JM, Abonyi MN, Nwabanne JT, Igbokwe PK (2025) Modeling and Optimization of Fibreboard Production from Corn Husk using Response Surface Methodology. UNIZIK Journal of Engineering and Applied Sciences, 4: 1920-33.

- Sharma N, Allardyce B, Rajkhowa R, Adholeya A, Agrawal RJFiPS (2022) A substantial role of agro-textiles in agricultural applications. 13: 895740.

- Rashid U, Rehman HU, Mustafa MRU, Hazmi B, Khurshid H, Ahmad J, Yu JJNJoC (2025) Comprehensive optimization study for the methanolysis of Linum usitatissimum oil using response surface methodology and artificial neural network.

- Sadeghpour A, Ozay GJAJfS, Engineering (2024) Investigating the Predictive Capabilities of ANN, RSM, and ANFIS in Assessing the Collapse Potential of RC Structures. 1-22.

- Aljuaydi F, Behera B, Elshewey A, Tarek ZJAM, Sciences I (2024) A Deep Learning Prediction Model to Predict Sustainable Development in Saudi Arabia. 18: 1345-66.

- Abonyi MN, Nwabanne JT, Ohale PE, Nwadike EC, Igbonekwu LI, Chukwu MM, Engineering E (2023) Application of RSM and ANFIS in the optimal parameter evaluation for crude oil degradation in contaminated water amended with PES. 8: 100483.

- Sagar YA, Reddy MSRL, Shilpa S, Jyothi N, Velivela A, Rao AN (2025) Neuro-Fuzzy Systems: Neural Networks and Fuzzy Logic Integration in Soft Computing. In Cybernetics, Human Cognition, and Machine Learning in Communicative Applications, 39-49.

- Gürsoy S, Ayrilmis NJF (2023) Effect of Lignin Modification of Recycled and Fresh Wood Fibers on Physical, Mechanical, and Thermal Properties of Fiberboard. 14: 2007.

- Hurtado-Figueroa O, Varum H, Prieto MI, Amaya RJG, Escamilla ACJH (2025) The Alkaline Treatment and its Influence on the Physicomechanical Properties of Plantain Pseudostem Fibers-A Comparative Study of Treated and Untreated Fibers.

- Shah AA, Seehar TH, Sharma K, Toor SS (2022) Biomass pretreatment technologies. In Hydrocarbon biorefinery, 203-28.

- Shahabazuddin M, Chandra TS, Meena S, Sukumaran R, Shetty N, Mudliar SJBt (2018) Thermal assisted alkaline pretreatment of rice husk for enhanced biomass deconstruction and enzymatic saccharification: Physico-chemical and structural characterization. 263: 199-206.

- Volpe V, Pantani RJPC (2025) Natural fiber‐reinforced light composites for the automotive industry.

- Deshmukh M, Yadav MJB (2025) Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials. 15: 230.

- Kanjilal R, Saenz JE, Uysal IJPB, Technology (2025) Large-scale data-driven uniformity analysis and sensory prediction of commercial banana ripening process. 219: 113203.

- Shanmugavalli M, Ignatia KMJJRPoE (2025) Comparative Study among MAPE, RMSE and R Square over the Treatment Techniques Undergone for PCOS Influenced Women. 19: E041223224190.

- Ahmed Y, Dutta KR, Nepu SNC, Prima M, AlMohamadi H, Akhtar PJRiE (2025) Optimizing photocatalytic dye degradation: A machine learning and metaheuristic approach for predicting methylene blue in contaminated water. 25: 103538.

- Mallick J, Alqadhi SJUC (2025) Explainable artificial intelligence models for proposing mitigation strategies to combat urbanization impact on land surface temperature dynamics in Saudi Arabia. 59: 102259.

- Abonyi MN, Anıagor CO, Menkiti MCJSJoE, Sciences N (2020) Statistical modelling of the adsorptive dephenolation of petroleum industry wastewater using ionic liquid treated clay. 38: 1099-112.

- El Azhari H, Cherif EK, El Halimi R, Azzirgue EM, Ou Larbi Y, Coren F, Salmoun FJS (2024) Predicting the Production and Depletion of Rare Earth Elements and Their Influence on Energy Sector Sustainability through the Utilization of Multilevel Linear Prediction Mixed-Effects Models with R Software. 16: 1951.

- Xv Y, Xiao B, Wei Z, Cao Y, Jiang Q, Li F, Xiao MJAR (2025) Interpretable CT Radiomics-based Machine Learning Model for Preoperative Prediction of Ki-67 Expression in Clear Cell Renal Cell Carcinoma.

- Eliwa EHI, El Koshiry AM, Abd El-Hafeez T, Omar AJIJoIS (2024) Optimal Gasoline Price Predictions: Leveraging the ANFIS Regression Model. 2024: 8462056.

- Ulama BSS, Hibatullah F, Habibi MR, Intelligence MJAC, Computing S (2024) Comparative Analysis of ANFIS and State‐ANFIS for Forecasting Cooking Oil Prices Based on Processed Palm Oil Yield (Crude Palm Oil). 2024: 3804265.

Tables at a glance

Figures at a glance