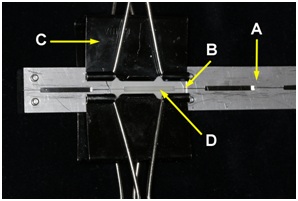

Figure 1 Specimen fabrication for non-repair group. A: mold; B: glass slide; C: clamp; D: sample.

Figure 1 Specimen fabrication for non-repair group. A: mold; B: glass slide; C: clamp; D: sample.

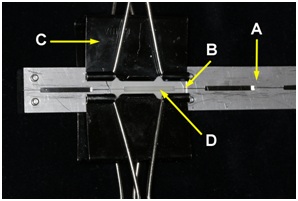

Figure 2 Specimen fabrication for aged repair groups. A:broken part; B: repaired part; C: joint between two parts.

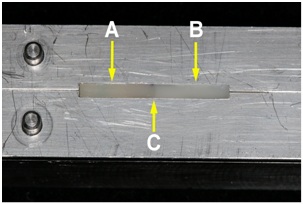

Figure 3 Specimen fabrication for immediate repair group. I:Fabrication of PVS template. A:prefabricated composite bar with the dimensions of 12.5×2×2 mm; II; injecting PVS material; B: Fabrication of a half-bars of provisional materials. III: PVS template with the dimensions of 12.5×2×2 mm; D: the fabricated half-bar of the sample, C: immediate repairing. E: repaired half-bar.

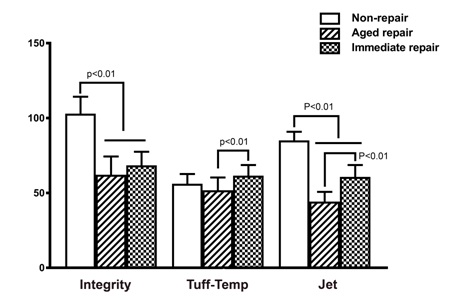

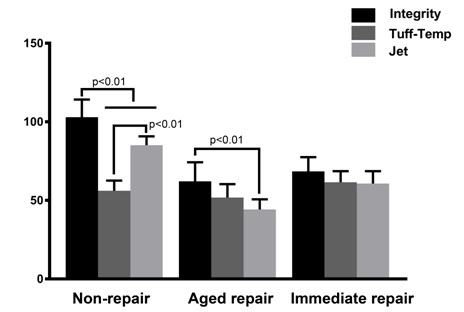

Figure 4 The effects of repair on flexural strength of three materials.

Figure 5 The effects of provisional material on flexural strength under different conditions

Brand Name |

Manufacturer |

Material type |

Shade |

Lot Number |

Tuff-Temp™ Plus |

Pulpdent Corp, Watertown, MA |

Rubberized-Urethane |

A2 |

150313 |

Integrity |

Dentsply, Milford, DE |

Bis-Acryl |

A2 |

150319 |

Jet |

Lang Dental Manufacturing Company, Wheeling, IL |

Methyl Methacrylate |

62 |

P-382015AH |

Table 1. Provisional restorative materials used in the study.

|

Non-Repair |

Immediate Repair |

Aged Repair |

Integrity |

102.93 (11.3) |

68.44 (9.1) |

62.11 (12.2) |

Tuff-Temp™ Plus |

56.10 (6.5) |

61.56 (7.1) |

51.77 (8.6) |

Jet |

85.10 (5.7) |

60.74 (7.9) |

44.24 (6.5) |

Table 2. Mean (SD) values for flexural strength test in all groups.

Source |

Sum of Squares |

df |

Mean Squares |

F-Ratio |

p Value |

Repair |

12568.992 |

2 |

6284.496 |

33.860 |

p<0.001 |

Material |

3140.279 |

1 |

3140.279 |

16.919 |

p<0.001 |

Table 3. Results of Two-way ANOVA.