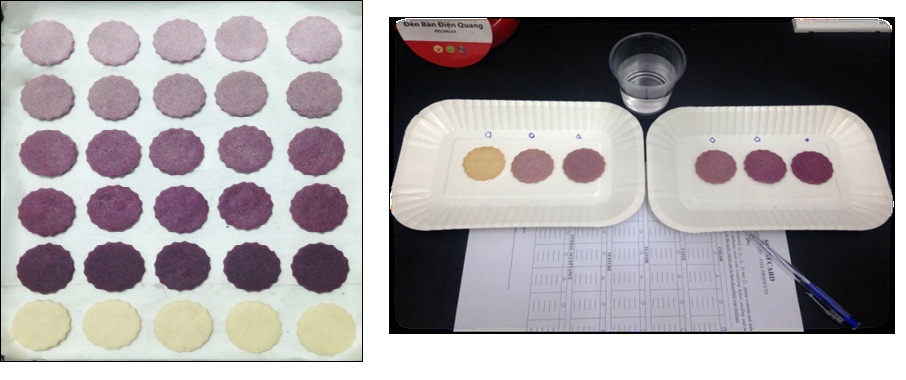

Figure 1 Purple sweet potatoes of variety HL 491 used in this study

Figure 1 Purple sweet potatoes of variety HL 491 used in this study

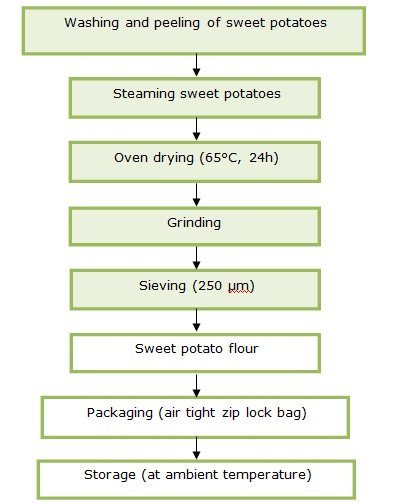

Figure 2 Flow chart for the preparation of sweet potato flour

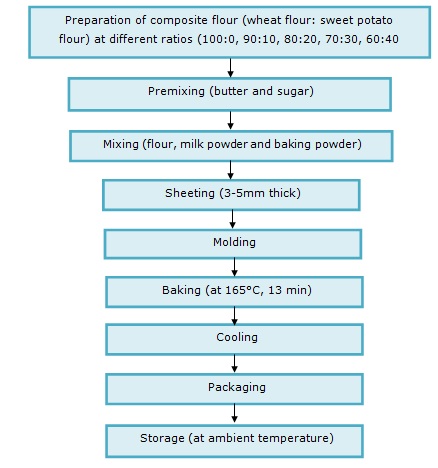

Figure 3 Flow chart for the preparation of biscuits

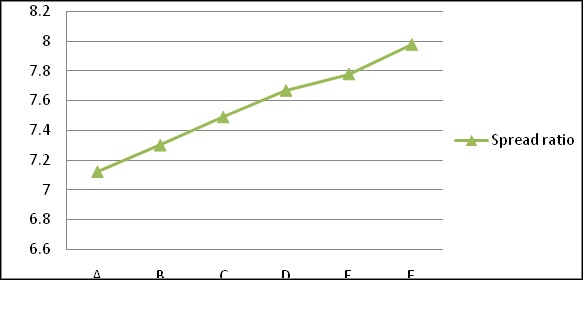

Figure 4 Effect of incorporating different levels of sweet potato flour on the spread ratio of biscuits.

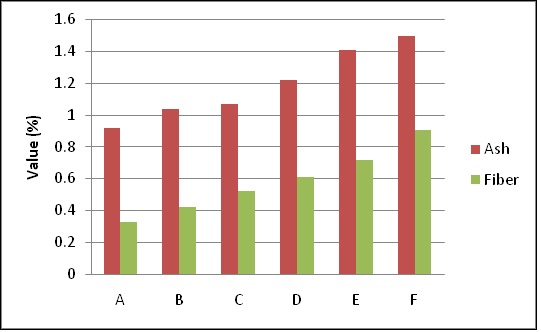

Figure 5 Effect of incorporating different ratio of sweet potato flour on the Ash and Fiber content of biscuits

Ingredients |

Samples (g) |

|||||

|

A |

B |

C |

D |

E |

F |

Wheat flour |

100 |

90 |

80 |

70 |

60 |

50 |

Sweet potato flour |

0 |

10 |

20 |

30 |

40 |

50 |

Powdered sugar |

15 |

15 |

15 |

15 |

15 |

15 |

Butter |

40 |

40 |

40 |

40 |

40 |

40 |

Baking powder |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

Salt |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

Table 1:Ingredients used in the preparation of biscuits

Components (%) |

Value* |

Moisture (d.w.b) |

7.14 ± 0.09 |

Ash |

1.98 ± 0.74 |

Fat |

0.44 ± 0.19 |

Protein |

2.48 ± 0.20 |

Crude fiber |

2.1 ± 0.00 |

Total carbohydrate |

85.80 ± 0.61 |

Table 2: Proximate values of purple sweet potato flour

*Values in the table represent the means ± standard deviations (n = 3 replicates) DWB = dry weight basis

Sample |

Bulk density (g/cm3) |

Water absorption Capacity (g/g) |

Oil absorption capacity (g/g) |

A |

0.69 ± 0.04a |

1.74 ± 0.06a |

2.23 ± 0.04a |

B |

0.70 ± 0.04a |

1.84 ± 0.05a |

2.21 ± 0.01ab |

C |

0.72 ± 0.01a |

1.89 ± 0.01a |

2.18 ± 0.01ab |

D |

0.73 ± 0.03a |

2.18 ± 0.04b |

2.17 ± 0.02ab |

E |

0.75 ± 0.02a |

2.39 ± 0.02c |

2.15 ± 0.01ab |

F |

0.77 ± 0.00a |

2.66 ± 0.08d |

2.13 ± 0.03b |

Table 3:Effect of incorporating sweet potato flour on the functional properties of the composite flours

*Values in the table represent the means ± standard deviations (n = 3 replicates) The values denoted by different letters in the same column are significantly different (p ≤0.05)

Physical property |

Value* |

Bulk density (g/cm3) |

0.94 ± 0.04 |

Water absorption capacity (g/g) |

2.76 ± 0.11 |

Oil absorption capacity (g/g) |

2.12 ± 0.03 |

Table 4:Functional properties of purple sweet potato flour

*Values in the table represent the means ± standard deviations (n = 3 replicates) The values denoted by different letters in the same column are significantly different (p ≤0.05)

Smpl |

Width |

Thickness (cm) |

Spread ratio |

Weight(g) |

Volume (cm3) |

Density (g/cm3) |

A |

4.09 ± 0.06a |

0.58 ± 0.01a |

7.12 ± 0.04a |

6.62 ± 0.03a |

7.56 ± 0.37a |

0.88 ± 0.05a |

B |

4.08 ± 0.08a |

0.56 ± 0.01ab |

7.30 ± 0.01b |

6.45 ± 0.07b |

7.28 ± 0.45a |

0.89 ± 0.04a |

C |

4.06 ± 0.08a |

0.54 ± 0.01abc |

7.49 ± 0.01c |

6.31 ± 0.03bc |

7.01 ± 0.44a |

0.91 ± 0.05a |

D |

4.06 ± 0.08a |

0.53 ± 0.01bc |

7.67 ± 0.07d |

6.13 ± 0.04d |

6.84 ± 0.35a |

0.90 ± 0.04a |

E |

4.07 ± 0.09a |

0.52 ± 0.01bc |

7.78 ± 0.06d |

6.16 ± 0.01cd |

6.79 ± 0.42a |

0.91 ± 0.06a |

F |

4.06 ± 0.08a |

0.51 ± 0.01c |

7.98 ± 0.02e |

6.07 ± 0.03d |

6.58 ± 0.42a |

0.93 ± 0.06a |

Table 5:Physical properties of developed biscuits

*Values in the table represent the means ± standard deviations (n = 3 replicates). The values denoted by different letters in the same column are significantly different (p ≤0.05)

Sample |

Moisture (%) |

Fat (%) |

Ash (%) |

Fiber (%) |

A |

5.96 ± 0.01a |

26.69 ± 0.87a |

0.92 ± 0.18a |

0.33 ± 0.04a |

B |

5.93 ± 0.01a |

26.51 ± 0.86a |

1.04 ± 0.13ab |

0.42 ± 0.03ab |

C |

5.81 ± 0.07a |

26.36 ± 0.87a |

1.07 ± 0.18ab |

0.52 ± 0.02bc |

D |

5.52 ± 0.06b |

26.25 ± 0.94a |

1.22 ± 0.02ab |

0.61 ± 0.01c |

E |

5.52 ± 0.03b |

25.69 ± 1.22a |

1.41 ± 0.03b |

0.72 ± 0.03d |

F |

4.89 ± 0.01c |

24.29 ± 1.46a |

1.50 ± 0.02b |

0.91 ± 0.01e |

Table 6:Proximate values of developed biscuits

*Values in the table represent the means ± standard deviations (n = 3 replicates). The values denoted by different letters in the same column are significantly different (p ≤0.05)

Sample |

Flavonoids (mg QE/g)* |

A |

4.80 ± 0.02a |

B |

5.25 ± 0.01b |

C |

6.07 ± 0.09c |

D |

6.36 ± 0.08d |

E |

6.45 ± 0.02d |

F |

7.51 ± 0.04e |

Table 7:Total Flavonoid Content of developed biscuits

QE = quercetin equivalence *Values in the table represent the means ± standard deviations (n = 3 replicates). The values denoted by different letters in the same column are significantly different (p ≤0.05)

Sample |

Color |

Taste |

Flavor |

Texture |

Overall acceptance |

A |

2.82a |

3.00a |

3.16a |

3.10a |

2.92a |

B |

3.00ab |

3.48ab |

3.44ab |

3.58a |

3.38ab |

C |

3.46bc |

3.64b |

3.62ab |

3.58a |

3.64b |

D |

3.72c |

3.96b |

3.96b |

3.50a |

3.80b |

E |

3.66c |

3.80b |

3.68ab |

3.54a |

3.80b |

F |

3.44bc |

3.68b |

3.60ab |

3.40a |

3.72b |

Table 8: Sensory evaluation scores of developed biscuits in term of color, taste, flavor, texture and overall acceptability in 5 - point scale.

*Average of 50 evaluations. The values denoted by different letters in the same column are significantly different (p ≤0.05)