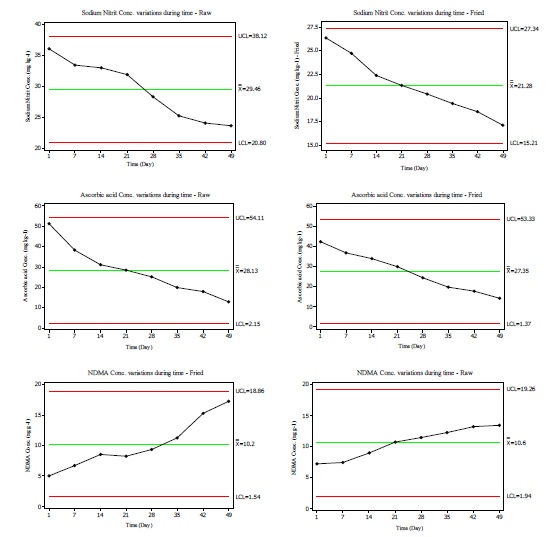

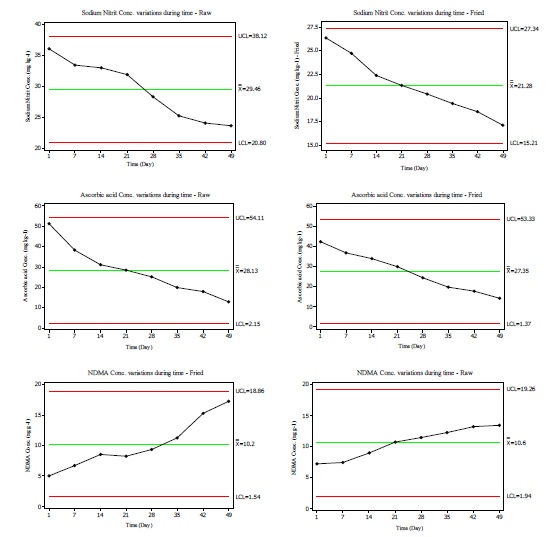

Figure 1 Ascorbic acid and sodium nitrite effect on nitrosamine formation in during time

Figure 1 Ascorbic acid and sodium nitrite effect on nitrosamine formation in during time

No. |

Name |

Polarity |

Boiling point (°C) |

CAS |

1 |

N-Nitrosodimethylamine (NDMA) |

log Kow*= -0.57 |

154.0 |

62-75-9 |

2 |

N-Nitrosomethylethylamine (NMEA) |

log Kow = 0.04 |

170.0 |

10595-95-6 |

3 |

N-Nitrosodiethylamine (NDEA) |

log Kow = 0.48 |

176.9 |

55-18-5 |

4 |

N-Nitrosodi-n-propylamine (NDPA) |

log Kow= 1.360 |

206.0 |

621-64-7 |

5 |

N-Nitrosodibutylamine (NDBA) |

log Kow = 2.63 |

237.0 |

924-16-3 |

6 |

N-Nitrosodiphenylamine (NDPhA) |

Log Kow= 3.13 |

268.0 |

86-30-6 |

7 |

1-Nitrosopiperidine (NPIP) |

log Kow = 0.36 |

219.0 |

100-75-4 |

8 |

1-Nitrosopyrrolidine (NPYR) |

log Kow = -0.19 |

214.0 |

930-55-2 |

9 |

Nitrosomorpholine (NMOR) |

log Kow = -0.44 |

225.0 |

59-89-2 |

*Kow's have redistributed from,30 |

||||

Table 1. Nitrosamines specifications

Operating parameters |

Values |

Injection volume (µL) |

2 |

Inlet temperature (oC) |

280 |

Flow (ml min-1) |

1.0 |

Temperature programming |

5 min isothermal at 60 °C, programmed to rise at 5 °C min-1 to 160 °C, rise at 20 °C min-1 to 240 °C,15 min isothermal at 240 °C |

Detector temperature (oC) |

300 |

Makeup-gas flow (N2) (mL min−1) |

20 |

Carrier gas |

Nitrogen |

Mode |

Pulsed splitless - Constant flow |

Table 2. Typical operating conditions for GC-FID.

Performance Characteristics |

||||||

Nitrosamine |

RT |

Linear dynamic range, LDR (mg L-1) |

The determination coefficient (R2) |

Limit of detection, LOD |

Limit of quantification, LOQ |

Relative standard deviation, RSD (%) |

NDMA |

11.5 |

1.0-10 |

0.997 |

0.4 |

1.0 |

7.2 |

NMEA |

12.6 |

1.0-10 |

0.989 |

0.4 |

1.0 |

8.6 |

NDEA |

13.3 |

1.0-10 |

0.988 |

0.4 |

1.0 |

8.2 |

NDPA |

16.7 |

1.0-10 |

0.984 |

0.4 |

1.0 |

10.5 |

NDBA |

21.0 |

2.0-10 |

0.982 |

0.7 |

2.0 |

11.7 |

NDPhA |

21.4 |

1.0-10 |

0.990 |

0.4 |

1.0 |

5.0 |

NPIP |

22.2 |

2.0-10 |

0.995 |

0.7 |

2.0 |

6.7 |

NPYR |

23.4 |

1.0-10 |

0.992 |

0.4 |

1.0 |

4.2 |

NMOR |

31.1 |

1.0-10 |

0.993 |

0.4 |

1.0 |

4.2 |

Table 3: Analytical performance data for nitrosamines determination.

N-nitrosamine |

Spiked Level(μg/L) |

Raw sausage |

Fried sausage |

||

Recovery |

%RSD |

Recovery |

%RSD |

||

NDMA |

1 5 10 |

70 85 95 |

5 4 3 |

72 83 97 |

5 4 3 |

NMEA |

1 5 10 |

68 87 92 |

5 5 3 |

70 85 95 |

6 4 5 |

NDEA |

1 5 10 |

71 85 95 |

4 5 3 |

68 85 95 |

6 3 4 |

NDPA |

1 5 10 |

70 85 95 |

6 4 3 |

67 83 96 |

4 4 3 |

NDBA |

5 10 |

85 92 |

5 3 |

85 95 |

4 3 |

NDPhA |

1 5 10 |

77 80 93 |

3 5 7 |

75 84 90 |

5 6 3 |

NPIP |

5 10 |

88 94 |

6 3 |

85 97 |

7 5 |

NPYR |

1 5 10 |

63 75 89 |

5 6 3 |

66 78 93 |

4 8 4 |

NMOR |

1 5 10 |

71 86 92 |

6 4 3 |

74 88 96 |

7 5 2 |

Table 4: Results of recoveries for nine spiked nitrosamines in sausage samples (n = 3).

Ref. |

Linear range (µg Kg-1) |

Real sample |

Recovery (%) |

Detection Limit (µg Kg-1) |

Quantitation limit (µg Kg-1) |

Method |

[3] |

0.25-500 |

Fast food, meat |

82-105.5 |

0.077-0.18 |

0.26 to 0.6 |

GC-NCD |

[35] |

- |

Potato |

103 |

0.001 |

0.003 |

GC-EID |

[18] |

- |

Sausages |

20-81.6 |

- |

400 |

SFE and MEKC |

[36] |

10000-200000 |

Water |

82-111 |

400-1600 |

0.13 |

GC-MS-PCI |

[6] |

0.25-500 |

Meat products |

60-105 |

0.01-0.12 |

0.03-0.36 |

SPE-GC-CI-MS |

[3] |

2-300 |

Meat products |

76-85 |

1.66–3.86 |

6.96-16.71 |

GC-GC-NCD |

[7] |

- |

Foodstuff |

80-120 |

0.10-0.30 |

- |

GC-PCI-MS/MS |

[1] |

1-100 |

Processed meats |

70-114 |

0.15-0.37 |

0.5-1.24 |

GC-MCI-MS |

[28] |

5-50 |

Food |

80-110 |

0.03-1.26 |

0.08-2.76 |

HPLC-APCI-MS/MS |

[37] |

0.3-100 |

Food products |

74-117 |

0.08-0.55 |

0.26-1.82 |

HPLC-UV |

[38] |

1-100 |

Processed meats |

70-114 |

0.15-0.37 |

0.50-1.24 |

GC-CI-MS |

[27] |

0.1-100 |

Water |

97.44-107.16 |

0.00078-0.0112 |

|

HS-SPME-GC-MS |

This work |

50-500000 |

Sausage |

63-97 |

0.4 |

0.5-1.0 |

GC-FID |

Table 5: Method analytical figures of merit for nitrosamines determination in sausage at a comparison to other methods