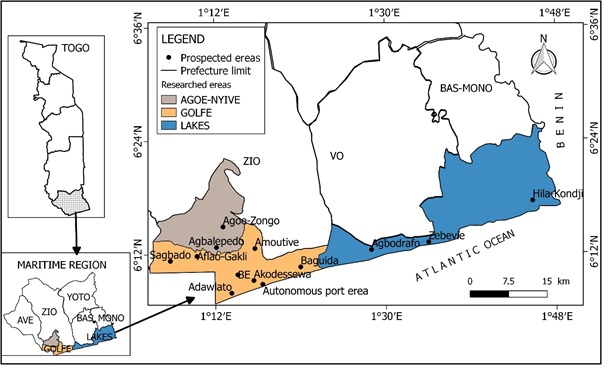

Locality (Prefectures) |

Number of producers surveyed |

Number distributors surveyed |

Number of consumers surveyed |

AGOE-NYIVE |

3 |

7 |

36 |

GOLFE |

7 |

8 |

43 |

LACS |

2 |

4 |

34 |

Total |

12 |

19 |

113 |

Table 1: Sample Size

|

|

Unit operations |

|||||||||||

|

|

Cleaning

|

Soaking

|

Milling

|

Fermentation |

Sieving

|

Fermentation

|

Incorporation of rice |

Incorporation of milk |

Cooking and addition of sugar and/or caramel |

Incorporation of milk |

Packaging |

|

|

|

||||||||||||

Methods |

1 |

+ |

+ |

+ |

+ |

+ |

- |

+ |

+ |

+ |

- |

+ |

|

2 |

+ |

+ |

+ |

+ |

+ |

- |

+ |

+ |

+ |

- |

+ |

||

3 |

+ |

+ |

+ |

- |

+ |

+ |

+ |

+ |

+ |

- |

+ |

||

4 |

+ |

+ |

+ |

+ |

+ |

- |

+ |

+ |

+ |

- |

+ |

||

5 |

+ |

+ |

+ |

- |

+ |

- |

+ |

- |

+ |

+ |

+ |

||

6 |

+ |

+ |

+ |

- |

+ |

- |

+ |

+ |

+ |

- |

+ |

||

7 |

+ |

+ |

+ |

+ |

+ |

- |

- |

- |

+ |

+ |

+ |

||

8 |

+ |

+ |

+ |

- |

+ |

+ |

+ |

- |

+ |

- |

+ |

||

9 |

+ |

+ |

+ |

- |

+ |

- |

- |

- |

+ |

- |

+ |

||

10 |

+ |

+ |

+ |

+ |

+ |

- |

- |

+ |

+ |

- |

+ |

||

11 |

+ |

+ |

+ |

- |

+ |

- |

- |

- |

+ |

+ |

+ |

||

12 |

+ |

+ |

+ |

+ |

+ |

- |

+ |

- |

+ |

+ |

+ |

||

Table 2: Presentation of the different unit operations according to various processes of production of the slurry containing

|

|

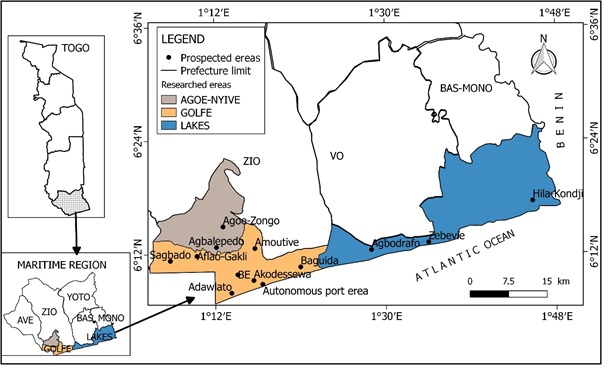

Equipment used |

Technological Operations |

Cleaning |

Tray, bassin, basket |

Soaking |

Bassin |

|

Milling |

Grinding mill grinding wheel, motar |

|

Wet sieving |

Sieve in nylon fabric (mesh less than 0,05 mm) |

|

Cooking |

Bassin |

|

Packaging |

Sachets for packaging (packaging of 50 and 100 FCFA) |

Table 3: Equipment used during the preparation of the porridges.

F CFA: Franc of French Colonies of Africa

|

Duration of operations |

Temperature of operations |

|

Technological operations |

Sorting |

20 – 30 minutes |

Ambiente (27 – 34 °C) |

Washing |

10 – 15 minutes |

Ambiente (27 – 34 °C) |

|

Soaking |

02 – 16 heures |

Ambiente (27 – 34 °C) |

|

Fine grinding |

07 – 12 minutes |

Ambiente (27 – 34 °C) |

|

Fermentation |

02 – 8 heures |

Ambiente (27 – 34 °C) |

|

Wet sieving |

30 – 40 minutes |

Ambiente (27 – 34 °C) |

|

Cooking |

55 – 90 minutes |

98 – 100 ºC |

|

Packaging |

90 – 120 minutes |

52 – 100 °C |

Table 4: Evaluations of some technological parameters for 3 kg of waste

Technological opération |

Quantity of incoming material of waste (g) |

Quantity of ingrédients (g) |

Quantity of material leaving (g) |

Yield |

Sorting |

4 200 |

- |

4000 |

0.95 |

Washing 1 |

4 000 |

Water: 7434 |

4045 |

1,01 |

Washing 2 |

4 045 |

Water: 7434 |

4100 |

1,01 |

Soaking |

4 100 |

Water: 7434 |

4360 |

1.06 |

Milling |

4 360 |

- |

4300 |

0.98 |

Wet sieving |

4 300 |

Water: 15 000 |

19300 |

4.49 |

Cooking |

19300 |

Rice : 0.25 kg ; Sugar : 0.5 kg ; Milk : 200g ; caramel : 0.25 kg |

20 000 |

1.03 |

Packaging |

2 package |

- |

- |

- |

Table 5: Material balance

|

|

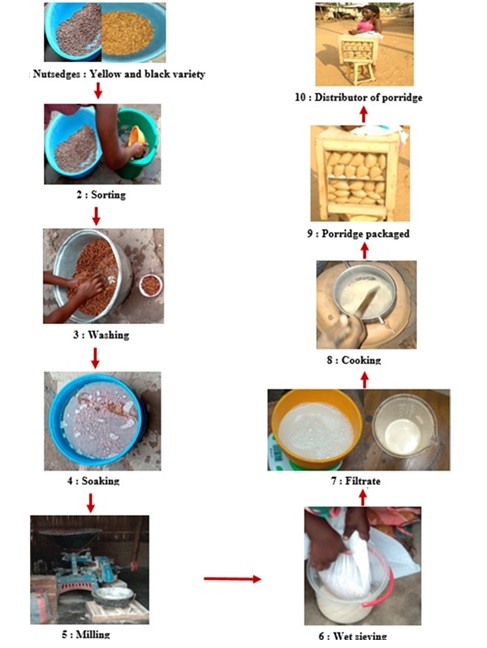

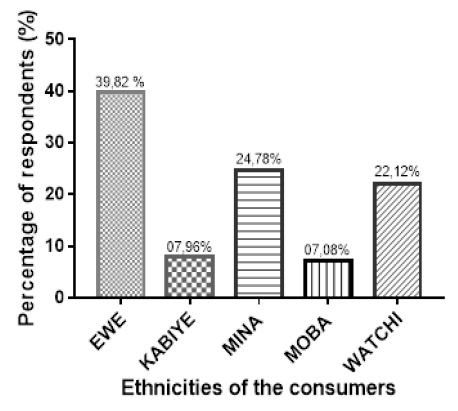

Sex |

Marital status |

||||

|

|

M (%) |

F (%) |

Other (%) |

Married (%) |

Single (%) |

Other (%) |

Respondents |

Producers |

0 |

100 |

0 |

58,33 |

33,33 |

8,33 |

Distributors |

5,26 |

94,74 |

0 |

15,78 |

47,37 |

36,84 |

|

Consumers |

83,19 |

16,81 |

0 |

30,97 |

55,75 |

13,27 |

|

Table 6: Sex and marital status of respondents (producers, distributors and consumers)

Material |

Number |

Amount |

Amortization (years) |

Amortization/month (F CFA) |

|

Bassin |

2 |

9000 |

5 |

150 |

|

Sieve |

1 |

300 |

1 |

25 |

|

Sieve |

1 |

400 |

1 |

34 |

|

Bowl |

2 |

150 |

1 |

13 |

|

Canvas |

1 |

300 |

1 |

25 |

|

Hearth |

1 |

2500 |

5 |

42 |

|

Pot |

1 |

7000 |

5 |

117 |

|

Palette |

1 |

300 |

5 |

5 |

|

Filtration system |

1 |

3000 |

5 |

60 |

|

Cashier for sale |

1 |

8000 |

5 |

134 |

|

Total |

12 |

30950 |

|

605 |

|

Table 7: Amortization of the material for the production of the nutsedge-based porridge

Operations |

Price/Unity for sale |

Quantity |

Cost (FCFA) |

Purchase of nutsedges |

1300 FCFA/measure |

2 local measures |

2600 |

Purchase of sugar |

600 FCFA/Kg |

1 kg |

600 |

Purchase of sachets |

250 FCFA/package |

2 packages |

500 |

Purchase of water |

25 FCFA/Bassin |

2 bassins |

50 |

Coal |

250 FCFA/package |

1 package |

250 |

Amortization/Production* |

- |

- |

37.8125 FCFA |

Unput** (1) |

- |

- |

4037.815 FCFA |

Output*** (2) |

- |

- |

11200 FCFA |

Profit margin |

- |

- |

7162.18175 FCFA |

Rate of return |

- |

- |

1.773 |

Table 8: Financial profitability of the production of nutsedge-based porridge

NB: * Monthly depreciation (605 FCFA) divided by the number of productions per month (16);

** Total expenditure for a slurry production from two measures of slurry (6 kg of porridge);

*** Sum generated by the sale of production of porridge from 6 kg of waste.