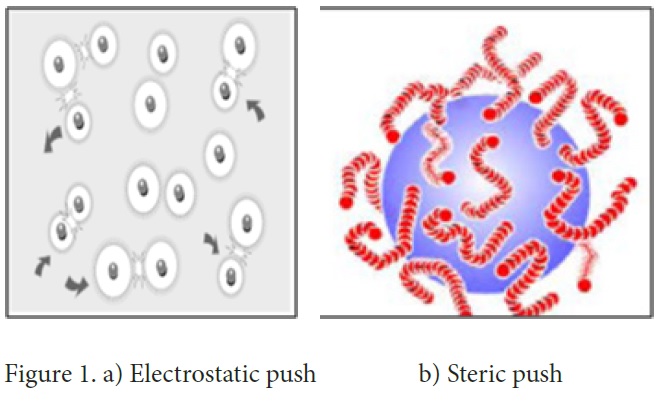

Figure 1

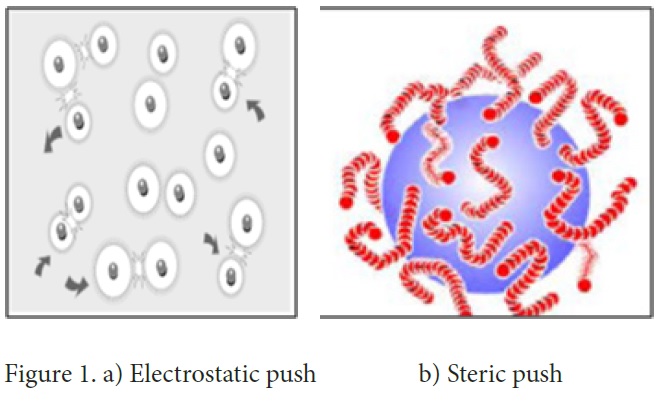

Figure 1

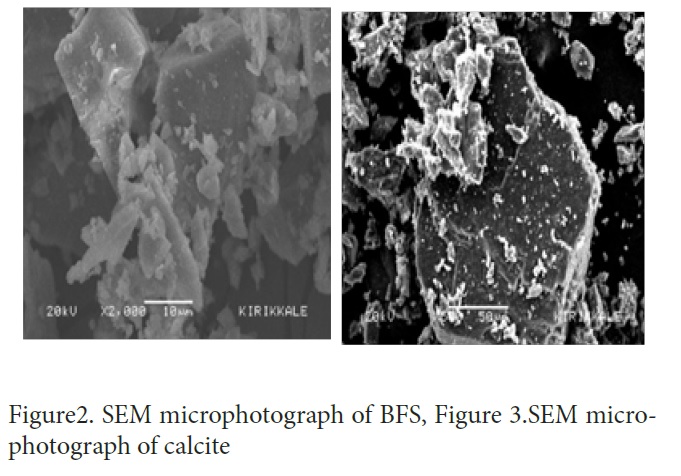

Figure 2

Figure 3

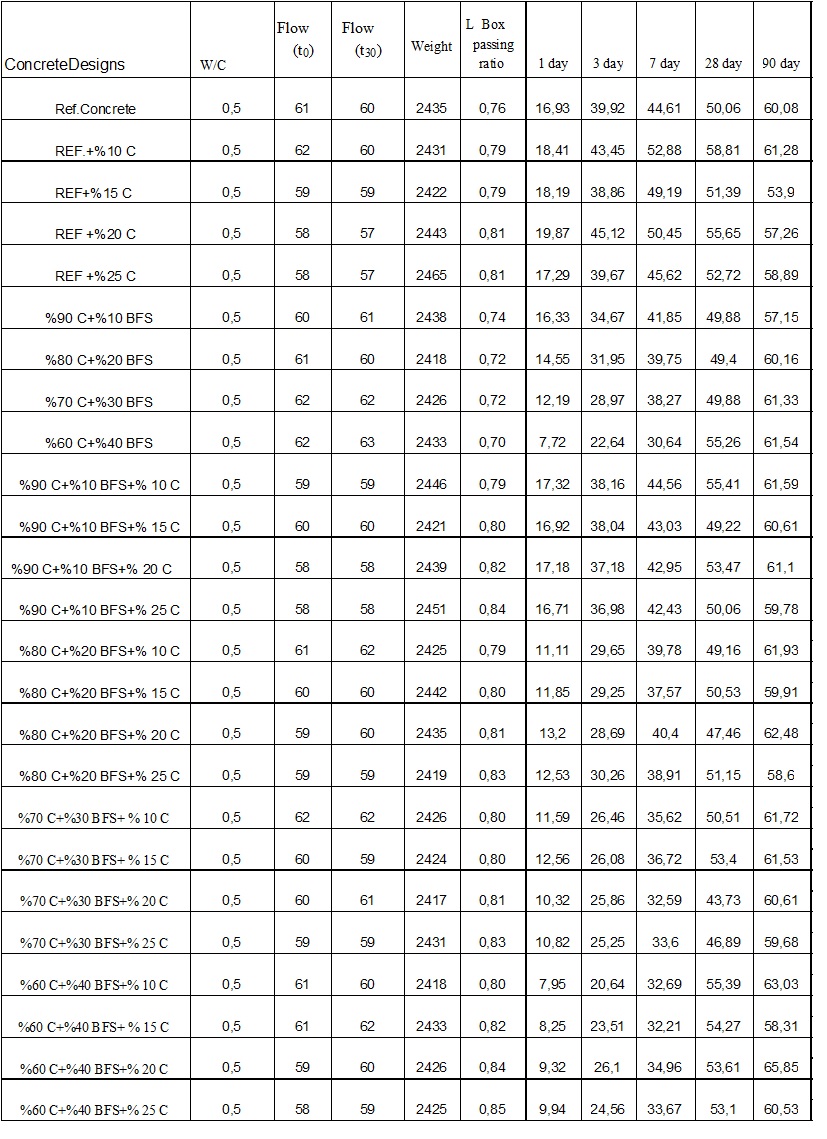

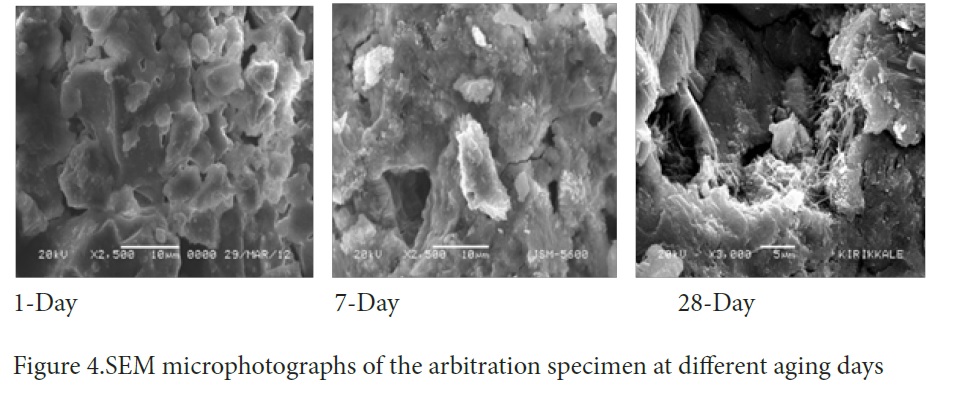

Figure 4

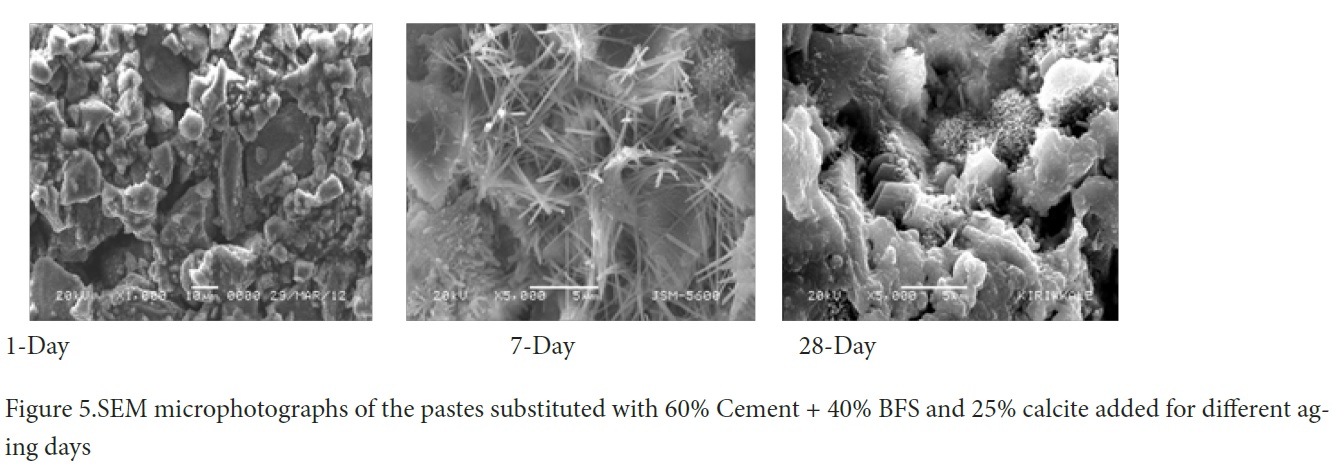

Figure 5

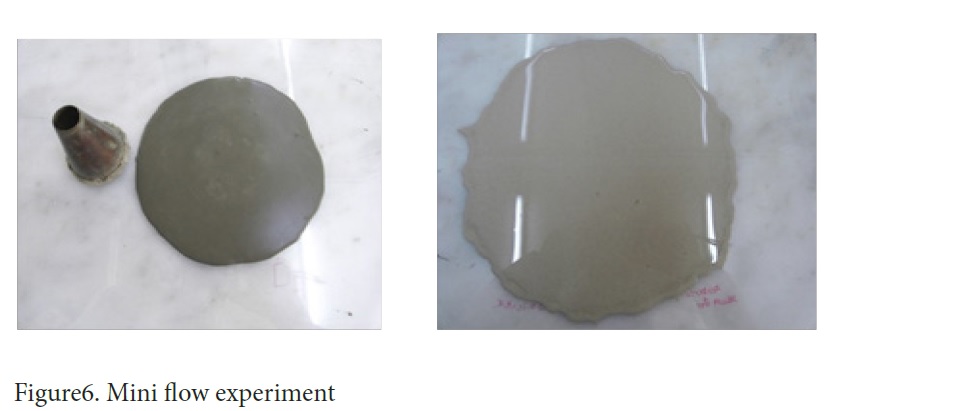

Figure 6

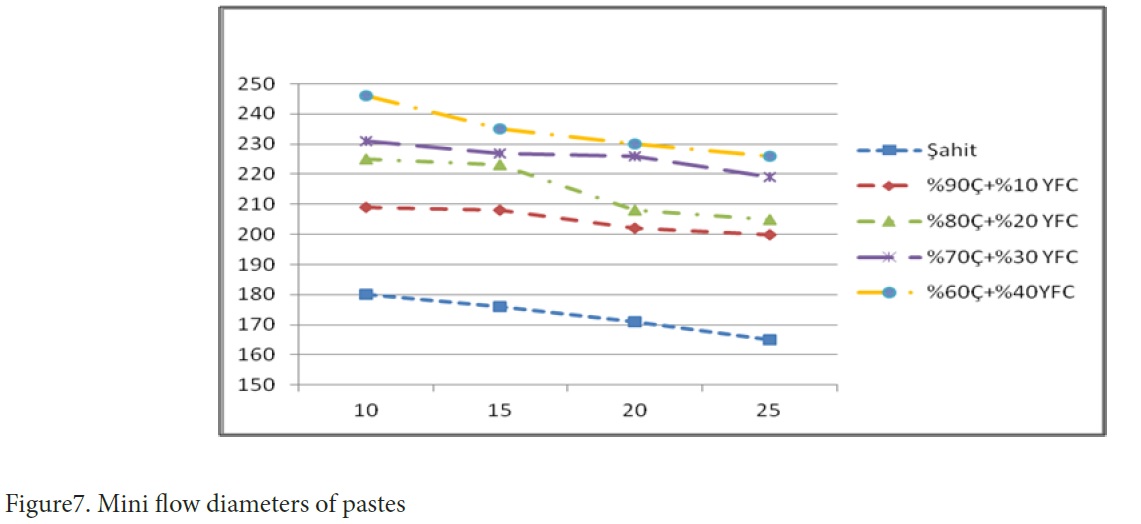

Figure 7

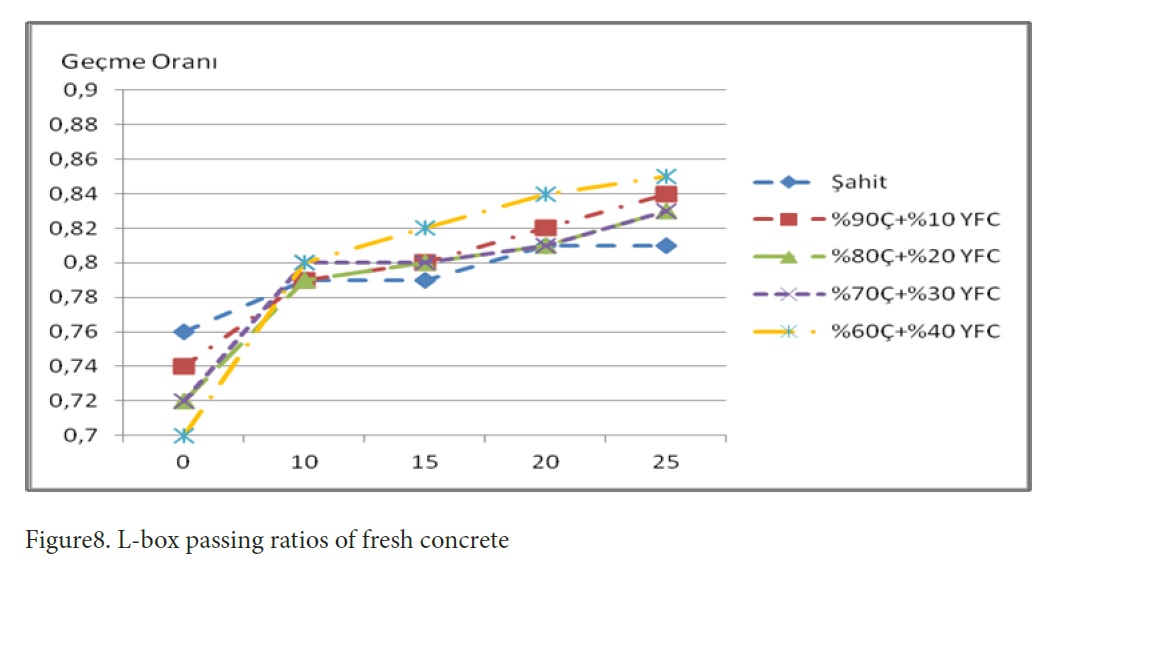

Figure 8

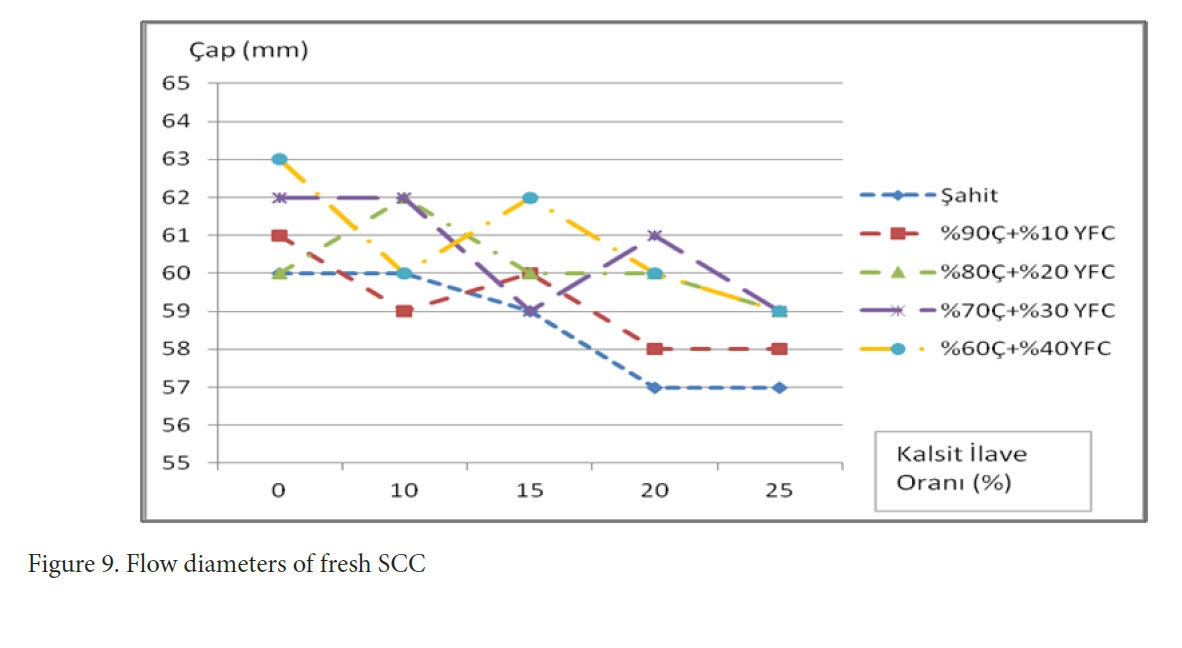

Figure 9

Figure 10

Figure 11

Physicalproperties |

Fine aggregate |

Coarse aggregate |

|

Sieve range |

0-4 mm |

4-12 mm |

12-22 mm |

Density (g/cm3) |

2.60 |

2.63 |

2.65 |

Water absorption (%) |

1.50 |

0.75 |

0.25 |

Table1 Physical properties of aggregates

Aggregate |

Last percentage (%) |

|||||||||

0.125 |

0.25 |

0.5 |

1 |

2 |

4 |

8 |

16 |

22 |

32 |

|

0-4 mm |

9 |

21 |

33 |

60 |

83 |

99 |

100 |

100 |

100 |

100 |

4-12 mm |

0 |

1 |

1 |

1 |

1 |

12 |

93 |

100 |

100 |

100 |

12-22 mm |

0 |

0 |

0 |

0 |

0 |

0 |

2 |

10 |

73 |

100 |

Table2 Aggregate sieve analysis

Properties |

Polycarboxylate |

Density (g/cm3) |

1,06 |

pH |

5,6 |

Drymaterialcontent(%) |

25 |

Table3 Physical properties of chemical additives

Kimyasal özellikler |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

Na2O |

K2O |

SO3 |

(%) |

21.16 |

4.05 |

2.26 |

63.7 |

1.30 |

0.30 |

0.35 |

3.30 |

Table4 Chemical properties of CEM I cement

Materials |

Material Amount (g) |

|||||||||||||||

Cement (g) |

1000 |

1000 |

1000 |

1000 |

||||||||||||

Water (g) |

330 |

330 |

330 |

330 |

||||||||||||

Calcite (%) |

10 |

15 |

20 |

25 |

||||||||||||

BFS (%) |

10 |

20 |

30 |

40 |

10 |

20 |

30 |

40 |

10 |

20 |

30 |

40 |

10 |

20 |

30 |

40 |

Additive (g) |

10 |

10 |

10 |

10 |

||||||||||||

Table15 Paste mixture amounts

Materials |

Material Amount (g) (kg/m3) |

||||||||||||||||

Cement |

350 |

315 |

280 |

245 |

210 |

||||||||||||

0-4 aggregate |

1000 |

965 |

930 |

895 |

860 |

||||||||||||

4-12 aggregate |

290 |

290 |

290 |

290 |

290 |

||||||||||||

12-22 aggregate |

570 |

570 |

570 |

570 |

570 |

||||||||||||

Water |

175 |

175 |

175 |

175 |

175 |

||||||||||||

Calcite (%10,15,20,25) |

0 |

35 |

52,5 |

70 |

87,5 |

35 |

52,5 |

70 |

87,5 |

35 |

52,5 |

70 |

87,5 |

35 |

52,5 |

70 |

87,5 |

BFS (%10,20,30,40) |

0 |

35 |

70 |

105 |

140 |

||||||||||||

|

3,5 |

3,5 |

3,5 |

3,5 |

3,5 |

||||||||||||

Theoretical unit weight |

2388,5 |

2388,5 |

2388,5 |

2388,5 |

2388,5 |

||||||||||||

Water/cement ratio |

0,50 |

0,50 |

0,50 |

0,50 |

0,50 |

||||||||||||

Table6 shows, the amount of mixture of SCC in 1 cubic meter is given