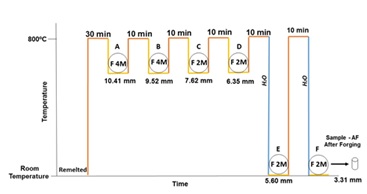

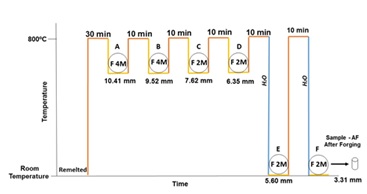

Figure 1:Schematic thermo mechanical process [6].

|

|

hp[μm] |

Hit[N/mm²] |

AF |

A |

1.201 |

2690 |

|

SD |

0.098 |

178 |

SOL |

A |

1.183 |

3110 |

|

SD |

0.305 |

907 |

350ºC / 30min |

A |

1.611 |

1772 |

|

SD |

0.250 |

371 |

400ºC / 30min |

A |

1.288 |

2661 |

|

SD |

0.128 |

327 |

450ºC / 30min |

A |

1.457 |

2333 |

|

SD |

0.252 |

430 |

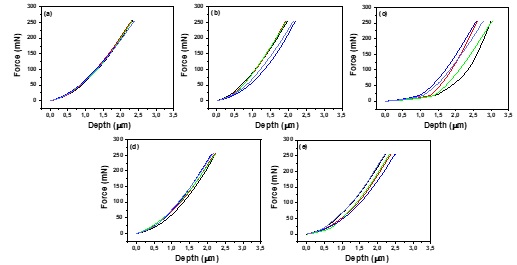

Table 1: -Permanent indentation depth after removal of the test force (hp), indentation hardness (Hit), elastic work (Welastic), and plastic work (Wplastic) for AF - After Forging, SOL - Solubilized, 350ºC/30min,400ºC/30min, and 450ºC/30min.

A – Average; SD - Standard Deviation

Figure 1:Schematic thermo mechanical process [6].

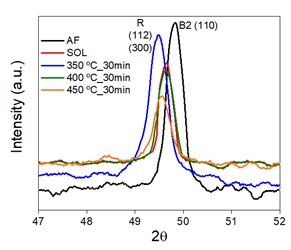

Figure 2:XRD patterns: AF - After Forging (black line) and SOL – Solubilized (red line), Heat Treated Samples: 350 ºC_30min (blue line), 400 ºC_30min (green line) and 450 ºC_30min (orange line).

Figure 3: Loading and unloading curves instrumented nanoindentation at 20ºC - Samples: (a) AF - After Forging, (b)SOL - Solubilized, (c) 350ºC/30min, (d) 400ºC/30min and (e) 450ºC/30min.

Figures at a glance